Overtightening High-Performance Liquid Chromatography (HPLC) guard columns to HPLC columns can cause several issues, leading to suboptimal chromatographic performance and potential damage to the equipment.

We offer three distinct direct-connect guard systems: EXP Holders, ROC Holders, and Trident Holders. It depends on the HPLC phase you are using. For more details, please refer here.

How to Choose the Right LC Guard Column

Guard columns are small, protective columns placed before the main analytical column to protect it from sample debris and HPLC system contaminants. Overtightening the guard column can cause physical damage to the PEEK ferrule. Excessive tightening can cause the PEEK ferrule to partially block the inlet frit of the HPLC column causing elevated backpressure. Overtightening can make it extremely challenging to remove the guard column or the HPLC column during maintenance or when switching columns. This difficulty can result in accidental damage to the column threads or the column itself (unable to remove ferrule).

What are the consequences of overtightening on the PEEK ferrule and guard cartridge? Below are some images illustrating the effects of excessive tightening on the components of the Trident guard holder and cartridge.

Figure 2

Guard Cartridge inlet side.

Figure 3

Ferrule that has been overtightened

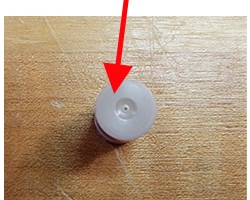

Figure 4

Figure 1: displays the PEEK ferrule immovably embedded within an HPLC column (column will need to be discarded).

Figure 2: exhibits the impression on the guard cartridge resulting from excessive tightening.

Figure 3: showcases a photograph of a PEEK ferrule damaged due to overtightening.

Figure 4: illustrates an unused PEEK ferrule (catalog 27476).

To prevent these problems, it is essential to adhere to our guidelines for attaching the guard column to the HPLC column. Usually, hand-tightening should suffice. A wrench may be necessary to ensure a leak-free connection, but it should only be turned an additional 1/8 to ¼ of a rotation beyond hand-tight. Please see the instruction sheets for the three different holders for more details.

Furthermore, it is equally crucial to routinely inspect and replace the ferrule to maintain effective sealing without the risk of overtightening. You will notice a new ferrule (figure 4) to start to expand and look like figure 3 when it needs to be replaced. Replace ferrule every few times the guard holder is removed or shows signs of wear.