The volatiles section in the CLP OLM 04.1 method in the US EPA’s Statement of Work (SOW) is derived principally from EPA drinking water method 524.2, and is followed for analysis of low- to medium-concentration samples of groundwaters or drinking waters collected from Superfund sites. To follow this method, the analyst must use a gas chromatograph/mass spectrometer system for analysis, in combination with a purge and trap system for concentrating and introducing the analytes from a 25mL sample. The method places a high demand on the chromatographic system, stipulating a set of response and recoverability criteria which must be met. System suitability is determined in part by the purging efficiency and inertness of the P&T apparatus, the inertness of the transfer pathway, the trapping and release characteristics of the trap, the selectivity and efficiency of the capillary GC column, and the sensitivity and scan rate capabilities of the MS. Further, sample throughput commonly is a concern in laboratories conducting these analyses.

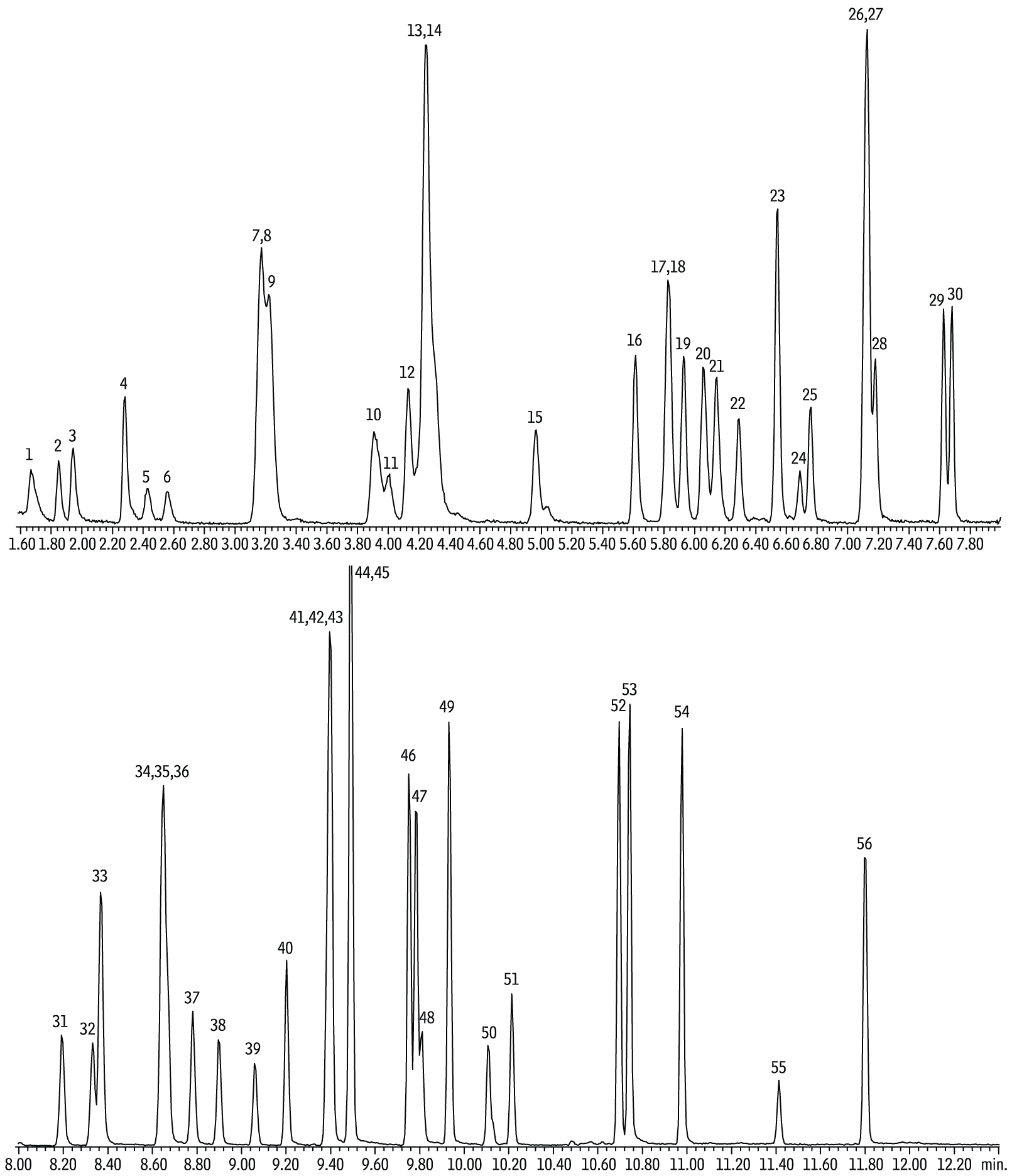

One important decision toward ensuring system suitability is to select the proper capillary column. A 30m x 0.25mm ID x 1.4µm Rtx-VMS column is an excellent choice for this application, as it is for many other purge and trap analyses for volatiles. The unique selectivity of the Rtx-VMS column allows baseline resolution of most of the target analytes in less than 12 minutes. Another stipulation of the method, 90% resolution of the gaseous components, is particularly challenging, but is easily attained by the Rtx-VMS column, as shown in Figure 1.

Good resolution and peak shape for volatiles, by CLP OLM 04.1 or other purge and trap GC methods, are difficult to achieve, particularly for the gases. An Rtx-VMS column meets or exceeds these demands, with a rapid analysis time that allows excellent sample throughput, and with good reproducibility. We highly recommend this column for these analyses.

Figure 1: Achieve good resolution and peak shape in purge and trap GC/MS analyses of volatiles by using an Rtx-VMS column.

GC_EV00812

Peaks

| Peaks |

|---|

| 37. | 1,1,2-Trichloroethane |

| 38. | Dibromochloromethane |

| 39. | 1,2-Dibromoethane |

| 40. | 2-Hexanone |

| 41. | chlorobenzene d5 (IS) |

| 42. | Chlorobenzene |

| 43. | Ethylbenzene |

| 44. | m-Xylene |

| 45. | p-Xylene |

| 46. | o-Xylene |

| 47. | Styrene |

| 48. | Bromoform |

| 49. | Isopropylbenzene |

| 50. | 4-Bromofluorobenzene (SS) |

| 51. | 1,1,2,2-Tetrachloroethane |

| 52. | 1,3-Dichlorobenzene |

| 53. | 1,4-Dichlorobenzene |

| 54. | 1,2-Dichlorobenzene |

| 55. | 1,2-Dibromo-3-Chloropropane |

| 56. | 1,2,4-Trichlorobenzene |

Conditions

| Rtx -VMS, 30 m, 0.25 mm ID, 1.40 µm (cat.# 19915) |

| CLP 04.1 VOA CAL2000 MegaMix, 2000μg/mL in methanol (cat.# 30456) |

| 502.2 Calibration Mix #1 (gases), 2000μg/mL in methanol (cat.# 30042) |

| VOA Calibration Mix #1 (ketones), 5000μg/mL in methanol/water (90:10) (cat.# 30006) |

| VOA Internal Standard Mix, 2500μg/mL in methanol (cat.# 30011) |

| VOA Surrogate Spike Mix, 2500ug/mL in methanol (cat.# 30004) |

| 25mL water |

| 20 ppb each analyte, ketones 100 ppb each |

| 1mm Split (cat.# 20793) |

| 200 °C |

| OI 4660 Eclipse Purge and Trap |

| #10 (Tenax/silica gel/carbon molecular sieve) |

| 11 min, flow 40 mL/min |

| 185 °C |

| 0.5 min @ 190 °C, flow 35 mL/min |

| 8 min @ 210 °C |

| injection port |

| 150 °C |

| 40 °C (hold 4 min) to 90 °C at 16 °C/min to 220 °C at 32 °C/min (hold 5 min) |

| 34 cm/sec @ 40 °C |

| MS |

| Scan |

| 150 °C |

| EI |

| 35-300 amu |

Products Mentioned

Rtx-VMS GC Kapillarsäule, 30 m, 0.25 mm ID, 1.40 µm

CLP 04.1 VOA CAL2000 MegaMix Standard, 2000 μg/mL, P&T Methanol, 1 mL/Ampulle

502.2 Kalibriermix #1 (Gase), 2000 µg/mL, P&T Methanol, 1 mL/Ampulle

VOA-Kalibriermix Nr. 1 (Ketone), 5000 μg/mL, P&T Methanol:Water (90:10), 1 mL/Ampulle

VOA Interner Standard Mix, 2500 μg/mL, P&T Methanol, 1 mL/Ampulle

VOA-Surrogat-Spike Mix, 2500 μg/mL, P&T Methanol, 1 mL/Ampulle

Top Taper Inlet Liner, 4.0 mm x 6.3 x 72, für Scion/Bruker/Varian GCs mit 1075/1077 Inlets, Standard-Deaktivierung mit deaktivierter Wolle, 5er Pack

-

Jason first came to "Chromatography Valley," the location of Restek's state-of-the-art manufacturing and development facility, as a student of chemistry at The Pennsylvania State University. Upon graduation, he ventured into the environmental and chemical industries for four years before finding a home at Restek, where he has been involved in GC column development, environmental applications, and SPE product development since 2002.

View all posts

EVAR3255