I’ve been getting a lot of questions recently regarding gas connections fittings, both from customers and other folks here at Restek, so I thought I’d spend some time demystifying some commonly used fittings in chromatography, starting with compression fittings.

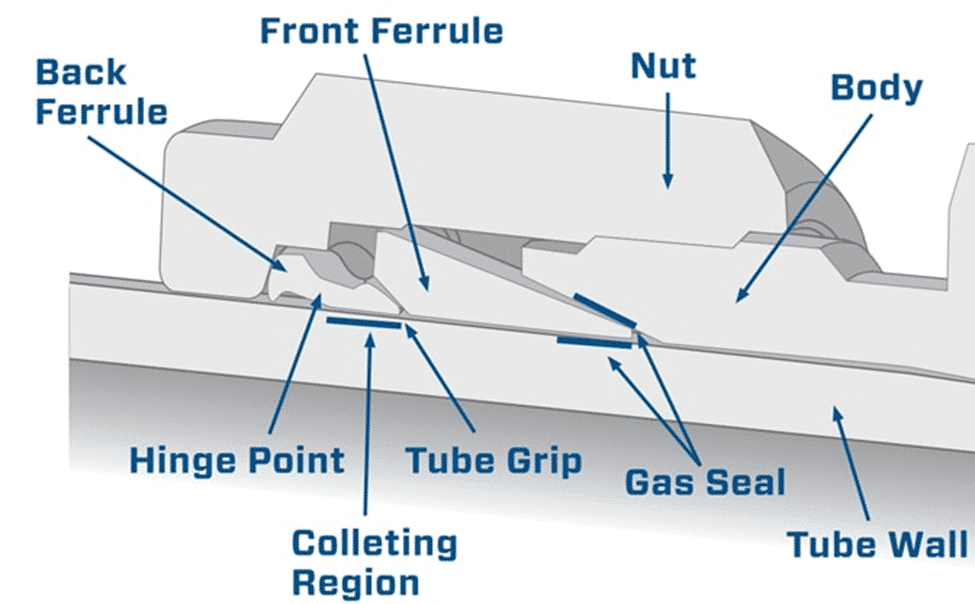

If you’ve worked with GCs, you’re almost certainly familiar with compression fittings. Gas fittings on GCs are compression fittings, and most labs plumb their lab gases using compression fittings as well. Compression fittings consist of a compression nut or screw, a ferrule, and a fitting body. As you tighten the nut the ferrule compresses into the body, creating a gas-tight seal as shown in Figure 1. It’s important to note that since the seal comes from the ferrule/body/tube interface, not the threads of the nut/body/tube, PTFE tape should not be used with compression fittings.

Figure 1: Compression fitting seal (https://pittsburgh.swagelok.com/en/about-us/blog/news-item-8-swagelok-tube-fitting-advantage-part-one)

Figure 1 comes from Swagelok, and Restek offers many fittings and valves from them. While they are one of the main manufacturers of quality compression fittings, other brands such as Yor-Lok and Hy-Lok are also commonly used. I’ve seen fittings from various manufacturers mixed and matched without issue, but this is generally against the manufacturer’s recommendations due to potential differences in shape and material, and in rare cases I’ve seen mixed fittings not seal properly, so I would advise caution when using different brands together.

Swagelok and similar style fittings use a two-piece ferrule design, which is better for higher pressure applications than single-piece designs (https://northerncal.swagelok.com/blog/single-ferrule-vs-double-ferrule-snc). In this design the front ferrule does tend to compress the tubing slightly though. For providing gas to the instrument this usually isn’t a problem, as the gas lines are usually larger (1/8”-1/2”) and any effect it may have on flow isn’t important, since the instrument has its own flow control. For smaller lines (1/16”) within an instrument though, this may be an issue, so Valco and similar fittings use a single ferrule that cuts into the tubing when compressed, instead of compressing the tubing along with it, as shown in Figure 2.

Figure 2: Single vs. dual ferrule connections (https://www.vici.com/ft_intro/fi_val1.php)

Proper tightening and installation of compression fittings is a common issue in labs, and I’ll dig deeper into that in the next installment of the blog, so stay tuned.