Introduction

The volatile component profiles of alcoholic beverages consist of a wide range of compounds, including acids, alcohols, aldehydes, and other trace-level flavor compounds. Analysts trained in the sensory evaluation of distilled liquors, wines, or beers tell us no two products are exactly alike. The unique sensory properties of different types and brands of distilled liquor products often are due to minor differences among the volatile components present. By using instrumental methods to qualitatively or quantitatively evaluate these differences, in addition to sensory techniques, quality assurance analysts can obtain a wealth of information about their products.

Gas chromatography (GC) is not only a powerful tool in the analysis of alcoholic beverages, but it is also a somewhat easy technique to use for the following reasons. Minimal sample preparation is required because the samples are analyzed in their original liquid state with alcohol or alcohol/water as the matrix. The flavor compounds tend to be volatile in nature, which fulfills one of the main requirements of GC. General detectors, such as the flame ionization detector (FID), or more information-rich detectors, such as the mass selective detector (MSD), can be used. Additionally, the ability to automate the analysis makes GC a very practical tool in a QA/QC environment. In this article, we will discuss how GC can be used to monitor the volatile components of alcoholic beverages.

Analysis of Alcohols and Aldehydes in Alcoholic Beverages

Alcoholic beverages contain a wide range of volatile compounds, including alcohols and short-chain aldehydes. GC can be used to analyze these compounds without requiring sample extraction. For example, AOAC International has published methods for the analysis of fusel alcohols (also known as fusel oils), methanol, ethanol, and higher order alcohols by GC [1].

Since capillary columns offer efficient separations, capillary GC is especially useful in the analysis of structurally similar compounds, such as fusel alcohols. However, selecting a GC column stationary phase with appropriate selectivity is essential for obtaining good peak shapes and excellent resolution of a range of alcohols. The two predominant fusel alcohols, 2-methyl-1-butanol (isoamyl alcohol) and 3-methyl-1-butanol (active amyl alcohol), are critical target compounds that must be resolved. Also, since alcoholic beverage analysis involves liquid samples that are predominantly water/ethanol-based, water, acetaldehyde, methanol, and ethanol must also be separated to avoid signal suppression during sample analysis. Acetic acid presents an additional challenge because it can exhibit poor peak shapes on some stationary phases.

| Tech Tip Use a gas-tight syringe to maximize syringe lifetime with ethanol samples. |

Choosing a GC Column with the Right Selectivity

To determine which GC column is best overall to use for alcoholic beverage analysis, three stationary phases with different polarity were evaluated: Rtx-502.2 (low-polarity); Rtx-VMS (unique polarity for solvents and volatiles); and Rtx-1301 (mid-polarity). Particular attention was paid to peak shapes and the resolution of specific compounds.

A standard containing many of the target compounds commonly tested for in alcoholic beverage analysis was prepared at 100 µg/mL in ethanol. Initial screening was conducted by FID. MSD analysis was then performed with a full scan method (10-400 m/z) to ensure that water was adequately resolved.

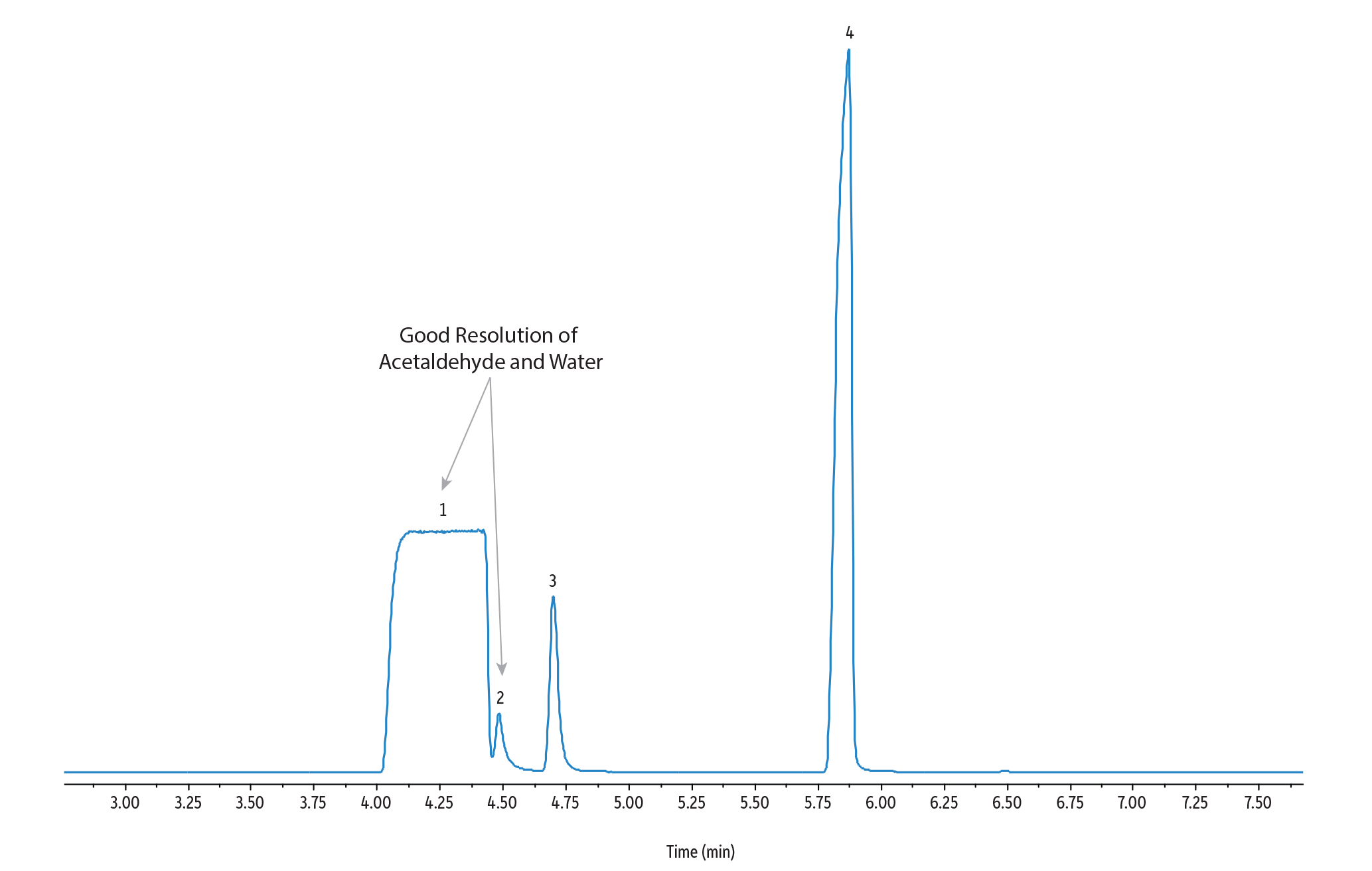

All three column phases yielded good separation of water, acetaldehyde, methanol, and ethanol. The Rtx-1301 column chromatogram shown in Figure 1 is representative of a typical separation of these compounds.

Figure 1: Typical Water/Acetaldehyde Separation on an Rtx-1301 Column Using GC-MS.

GC_FF1389

Peaks

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 1. | Water | 4.312 | |

| 2. | Acetaldehyde | 4.483 | 100 |

| 3. | Methanol | 4.699 | 100 |

| 4. | Ethanol | 5.871 | 100 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.00 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Custom acetaldehyde, methanol, and ethanol standard in water |

| Diluent: | Water |

| Conc.: | 100 µg/mL |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz Precision inlet liner with wool, 4.0 mm x 6.3 x 78.5 (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 141.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 2.45 min) to 220 °C at 7 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 30.261 cm/sec @ 35 °C |

| Detector | MS | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mode: | Scan | ||||||||

| Scan Program: | |||||||||

| |||||||||

| Transfer Line Temp.: | 280 °C | ||||||||

| Analyzer Type: | Quadrupole | ||||||||

| Source Temp.: | 230 °C | ||||||||

| Quad Temp.: | 150 °C | ||||||||

| Electron Energy: | 70 eV | ||||||||

| Solvent Delay Time: | 0.0 min | ||||||||

| Tune Type: | PFTBA | ||||||||

| Ionization Mode: | EI | ||||||||

| Instrument | Agilent 7890A GC & 5975C MSD | ||||||||

| Notes | The EZGC method translator was used to establish the MS conditions. | ||||||||

| Did You Know? Fusel alcohols are higher order (i.e., secondary or tertiary) alcohols, traces of which usually are present in all beers. They are produced through a pathway very similar to the pathway for ethanol, the preferred alcohol for beer. Fusel alcohols contribute a hot, spicy, solvent-like flavor and an alcohol “burn.” Small amounts of these components can be desirable in a strong ale or barley wine, but they can be offensive and therefore are unwanted in a Pilsner or other lager. In addition to their influence on flavor, they usually cause low carbonation and poor head retention in bottle-conditioned beers because they are deadly to yeast. Higher fermentation temperatures can produce excessively rapid yeast growth and yeast mutations, which, in turn, stimulate the formation of these components. |

|

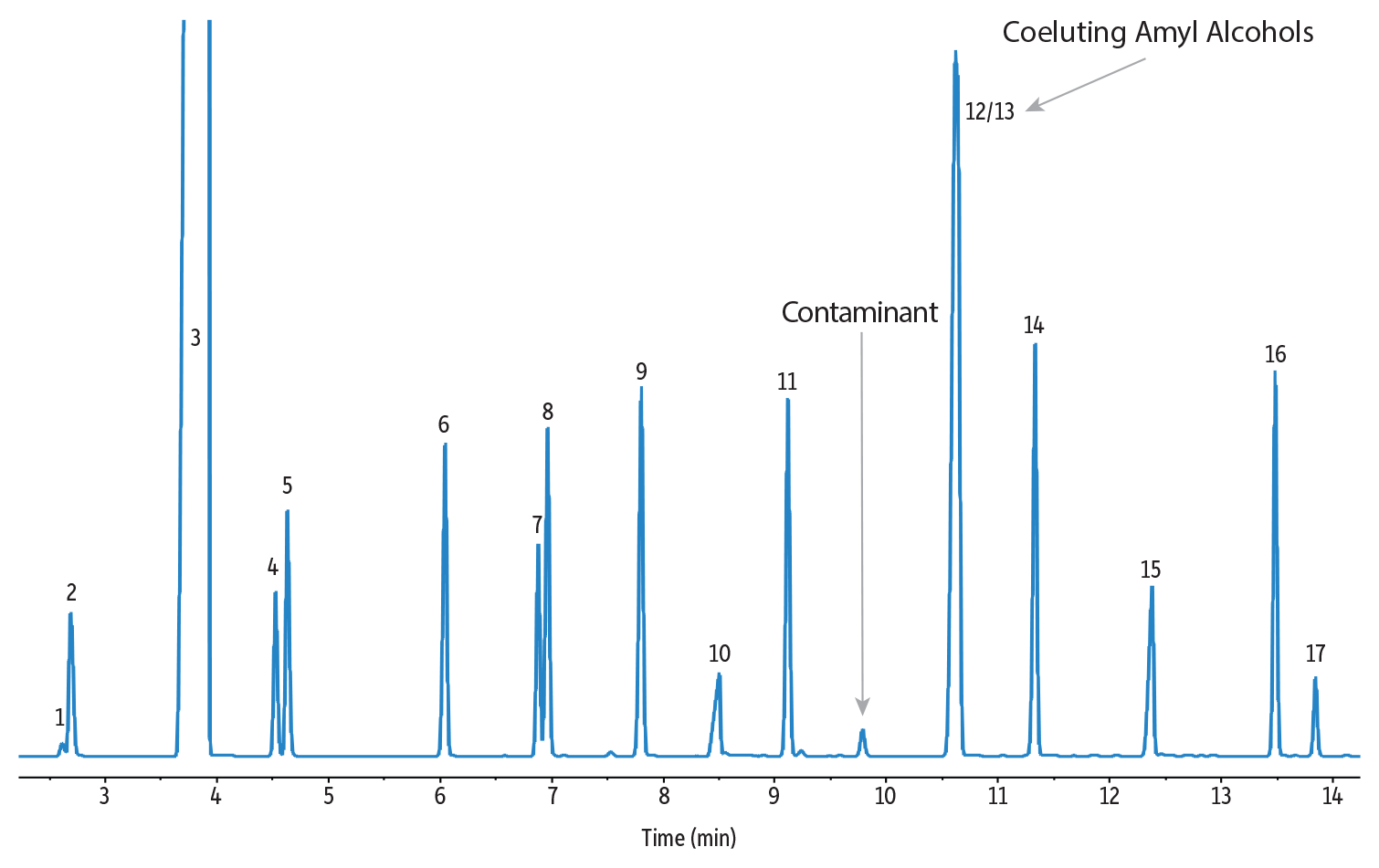

The first phase evaluated for resolution and peak shape was the Rtx-VMS phase in a 30 m x 0.25 mm ID x 1.40 µm column format (cat.# 19915). While the separation of water, acetaldehyde, and methanol was adequate (similar to the Rtx-1301 column), the Rtx-VMS column does not resolve 2-methyl-1-butanol (isoamyl alcohol) and 3-methyl-1-butanol (active amyl alcohol) as shown in Figure 2. Even with the oven set to 35 °C and held isothermally, the amyl alcohols coelute regardless of the Rtx-VMS column dimensions.

Figure 2: Common alcoholic beverage target compounds 2-methyl-1-butanol and 3-methyl-1-butanol are not resolved on an Rtx-VMS column (peaks 12 and 13).

GC_FF1385

Peaks

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 1. | Acetaldehyde | 2.607 | 100 |

| 2. | Methyl alcohol | 2.685 | 100 |

| 3. | Ethanol | 3.917 | |

| 4. | Acetone | 4.521 | 100 |

| 5. | Ethyl formate | 4.627 | 100 |

| 6. | 1-Propanol | 6.040 | 100 |

| 7. | Ethyl acetate | 6.874 | 100 |

| 8. | 2-Butanol | 6.959 | 100 |

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 9. | 1-Propanol, 2-methyl- | 7.799 | 100 |

| 10. | Acetic acid | 8.497 | 100 |

| 11. | Ethane, 1,1-diethoxy- | 9.112 | 100 |

| 12. | 3-Methyl-1-butanol | 10.614 | 100 |

| 13. | 2-Methyl-1-butanol | 10.632 | 100 |

| 14. | 1-Pentanol | 11.328 | 100 |

| 15. | Propylene glycol | 12.375 | 100 |

| 16. | Isoamyl acetate | 13.478 | 100 |

| 17. | Furfural | 13.839 | 100 |

Conditions

| Column | Rtx-VMS, 30 m, 0.25 mm ID, 1.40 µm (cat.# 19915) |

|---|---|

| Standard/Sample | Custom beverage analysis mix |

| Diluent: | Ethanol |

| Conc.: | 100 µg/mL Final on-column concentration is 1 ppm. |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz, precision inlet liner, 4.0 mm x 6.3 x 78.5, for Agilent GCs, w/quartz wool (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 144.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 31.993 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

| Sample Preparation | Single component compounds combined to make final custom mix in ethanol. |

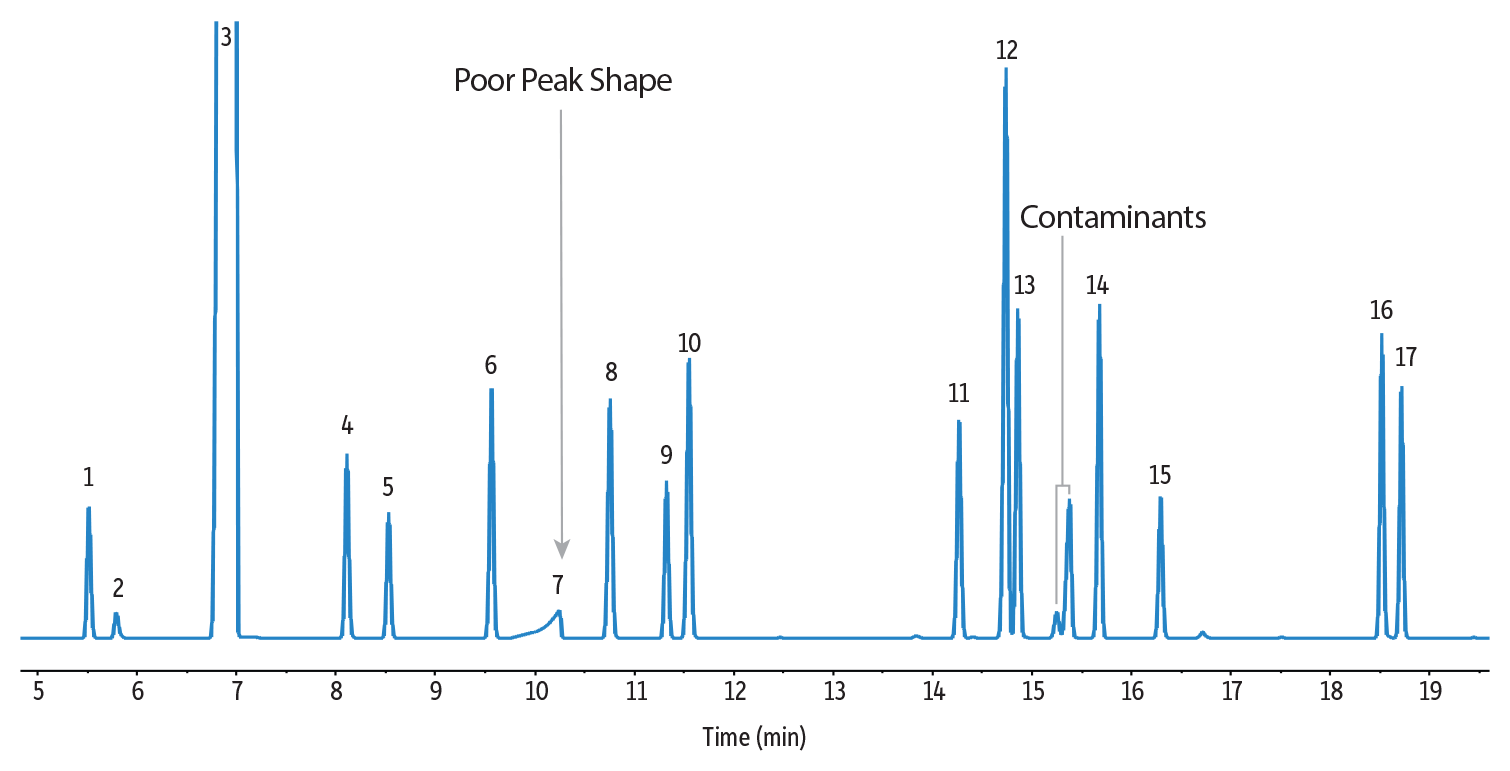

The Rtx-502.2 phase in a 60 m x 0.25 mm ID x 1.40 µm column format (cat.# 10916) offered excellent resolution and an acceptable analysis time for all target compounds. However, the acetic acid peak shape shows fronting, which indicates poor solubility of acetic acid in the low-polarity stationary phase (Figure 3).

Figure 3: Acetic acid exhibits poor peak shape on an Rtx-502.2 column, indicating poor solubility in the stationary phase (peak 7).

GC_FF1387

Peaks

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 1. | Acetaldehyde | 5.785 | 100 |

| 2. | Methanol | 5.508 | 100 |

| 3. | Ethanol | 6.971 | 100 |

| 4. | Acetone | 8.103 | 100 |

| 5. | Ethyl formate | 8.523 | 100 |

| 6. | 1-Propanol | 9.559 | 100 |

| 7. | Acetic acid | 10.244 | 100 |

| 8. | 2-Butanol | 10.750 | 100 |

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 9. | Ethyl acetate | 11.318 | 100 |

| 10. | Isobutanol | 11.544 | 100 |

| 11. | Acetal | 14.260 | 100 |

| 12. | 3-Methyl-1-butanol | 14.730 | 100 |

| 13. | 2-Methyl-1-butanol | 14.850 | 100 |

| 14. | Propylene glycol | 15.670 | 100 |

| 15. | n-Amyl alcohol | 16.286 | 100 |

| 16. | Isoamyl acetate | 18.511 | 100 |

| 17. | Furfural | 18.708 | 100 |

Conditions

| Column | Rtx-502.2, 60 m, 0.25 mm ID, 1.4 µm (cat.# 10916) |

|---|---|

| Standard/Sample | Custom beverage analysis |

| Diluent: | Ethanol |

| Conc.: | 100 µg/mL 100:1 split |

| Injection | |

| Inj. Vol.: | 1.0 µL split (split ratio 100:1) |

| Liner: | Topaz precision split liner (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 140 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.503 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

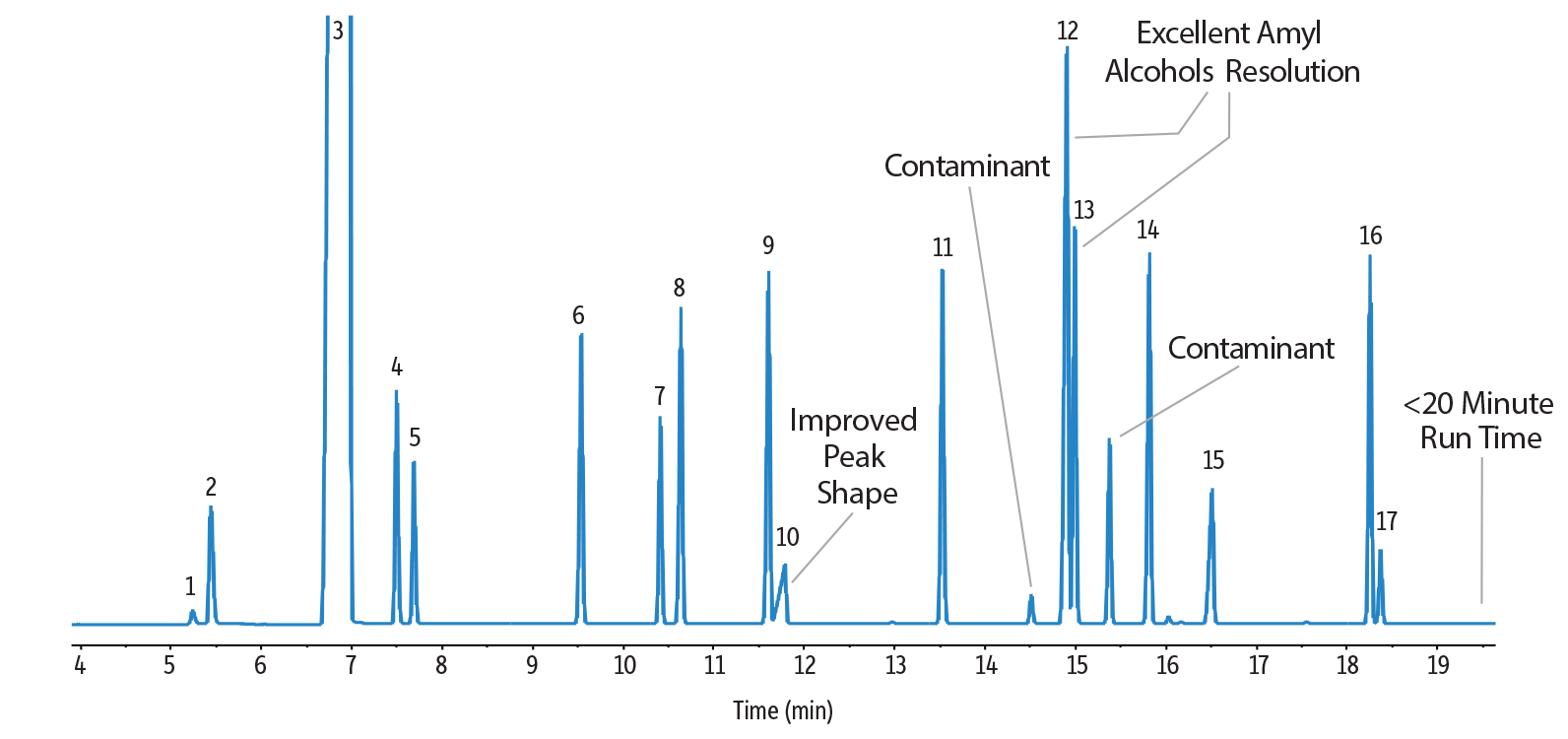

The last column evaluated was an Rtx-1301 phase in a 60 m x 0.25 mm ID x 1.00 µm format (cat.# 16056). This column offered the best overall chromatography, particularly in terms of peak shape and resolution of the critical pairs. Importantly, the 2-methyl-1-butanol and 3-methyl-1-butanol peaks are adequately resolved. In addition, by using the higher polarity Rtx-1301 stationary phase (a cyanopropylphenyl-type polysiloxane phase) compared to the lower polarity Rtx-502.2 (a phenylmethyl-type polysiloxane phase), the acetic acid peak shape was much improved (Figure 4). This occurs because acetic acid is more soluble in the Rtx-1301 phase. Because the Rtx-1301 column produced the best overall chromatography in less than 20 minutes, it is the recommended column for GC analysis of alcoholic beverages.

Figure 4: The Rtx-1301 column shows the best overall chromatography for targeted alcoholic beverage compounds.

GC_FF1388

Peaks

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 1. | Acetaldehyde | 5.230 | 100 |

| 2. | Methyl alcohol | 5.431 | 100 |

| 3. | Ethanol | 6.911 | 100 |

| 4. | Acetone | 7.476 | 100 |

| 5. | Ethyl formate | 7.674 | 100 |

| 6. | 1-Propanol | 9.517 | 100 |

| 7. | Ethyl acetate | 10.400 | 100 |

| 8. | 2-Butanol | 10.620 | 100 |

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 9. | Isobutanol | 11.590 | 100 |

| 10. | Acetic acid | 11.753 | 100 |

| 11. | Acetal | 13.517 | 100 |

| 12. | 3-Methyl-1-butanol | 14.884 | 100 |

| 13. | 2-Methyl-1-butanol | 14.975 | 100 |

| 14. | 1-Pentanol | 15.802 | 100 |

| 15. | Propylene glycol | 16.490 | 100 |

| 16. | Isoamyl acetate | 18.246 | 100 |

| 17. | Furfural | 18.363 | 100 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Custom beverage analysis standard |

| Diluent: | Ethanol |

| Conc.: | 100 µg/mL |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz precision split liner (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 140 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 7 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.457 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

Alcoholic Beverage Sample Analysis

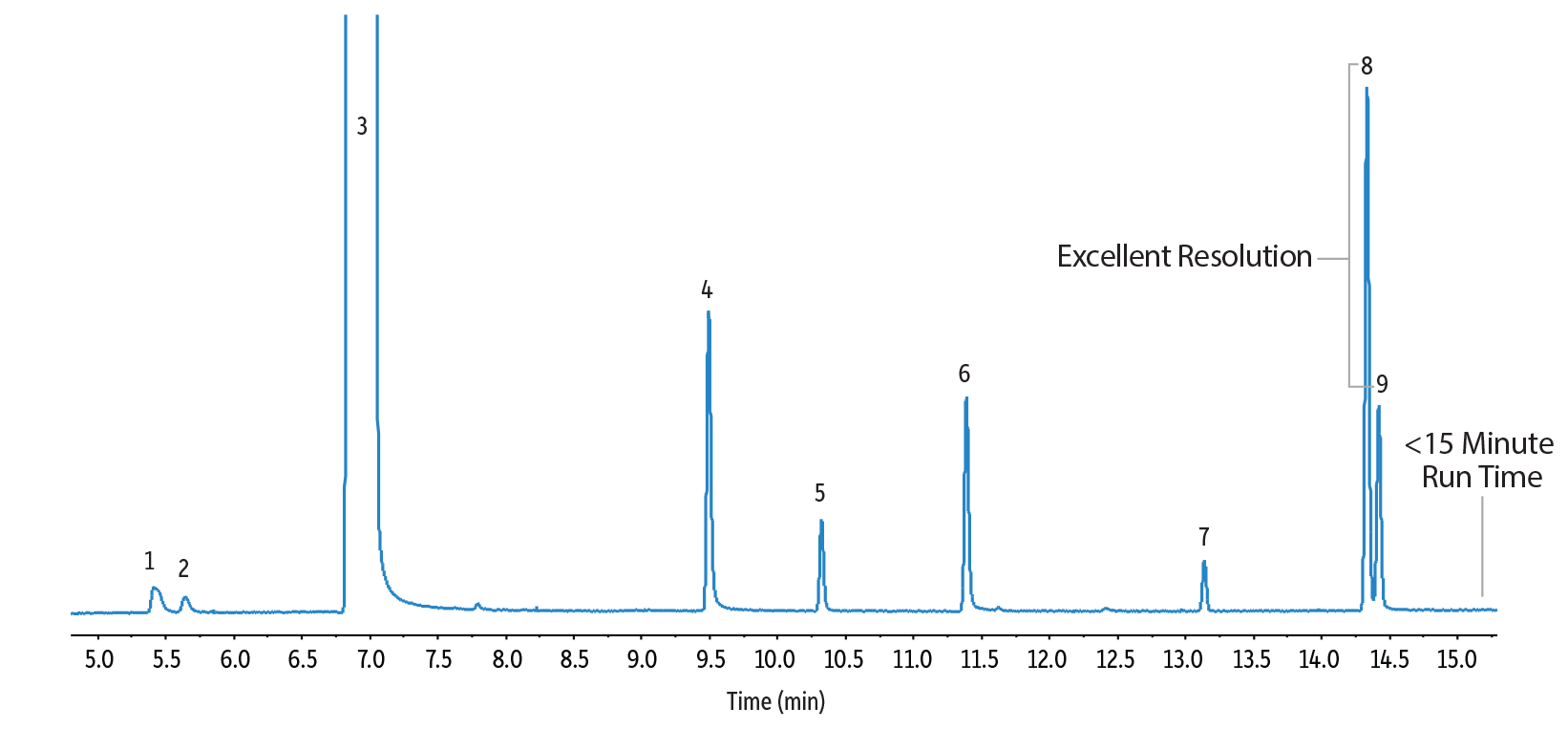

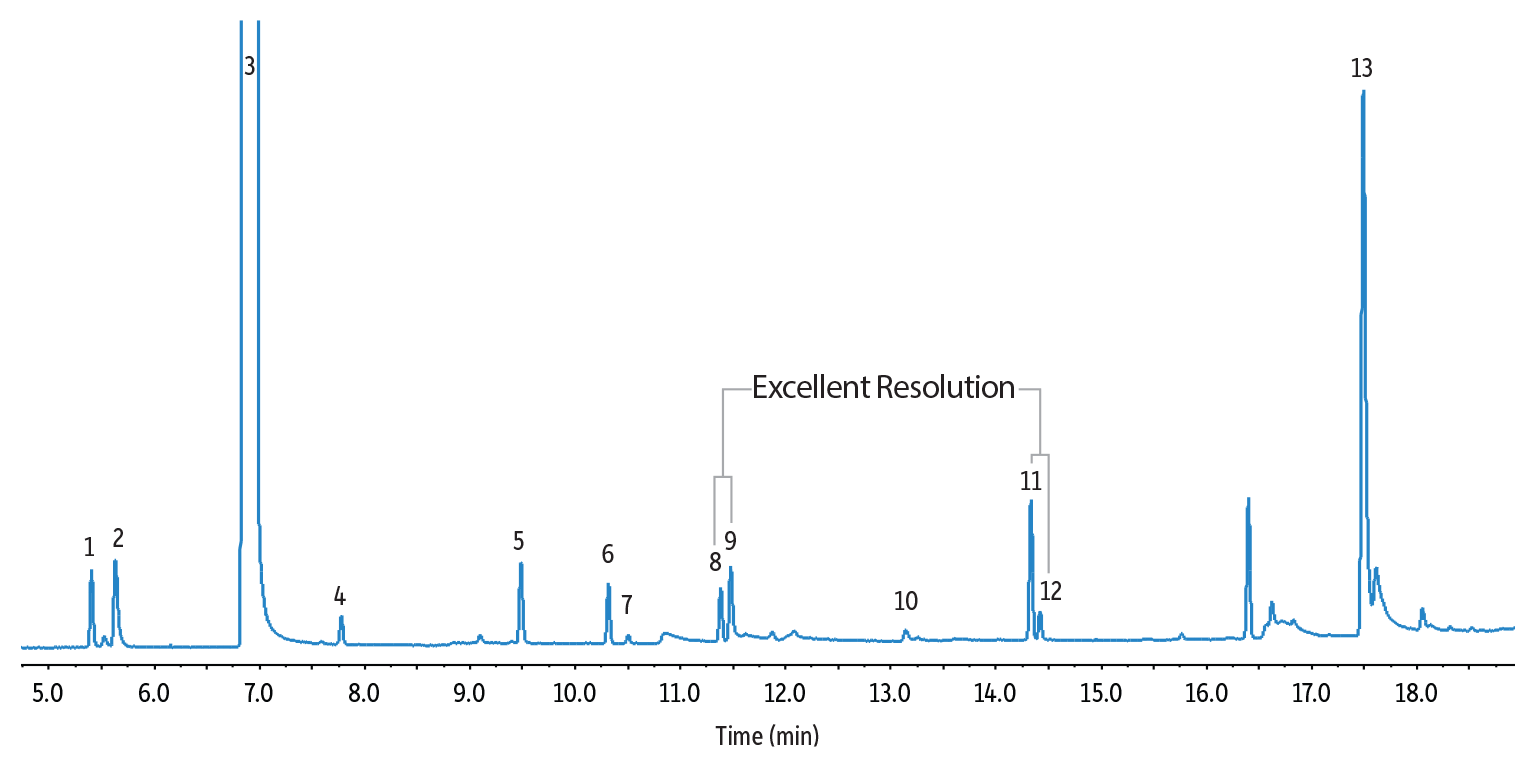

To confirm the performance of the Rtx-1301 column for targeted alcoholic beverage compounds, real-world alcohol samples were analyzed. Data was collected with both an FID and an MS detector with the method initially developed by GC-FID and then transferred to GC-MS. To ease this transition, Restek’s EZGC method translator was used. The translation provided by this tool proved to be an excellent starting point for the MS method—it was generated in seconds and needed only minor optimization and adjustment of the temperature program to ensure that isobutanol and acetic acid were adequately resolved. For example, Figures 5 and 6 show the same chromatography for rye whiskey analysis by GC-FID and GC-MS, respectively; note the excellent resolution between the isobutanol and acetic acid as well as the separation of the 2-methyl-1-butanol and 3-methyl-1-butanol peaks. The acetic acid peak shape is satisfactory, and the analysis time is less than 15 minutes.

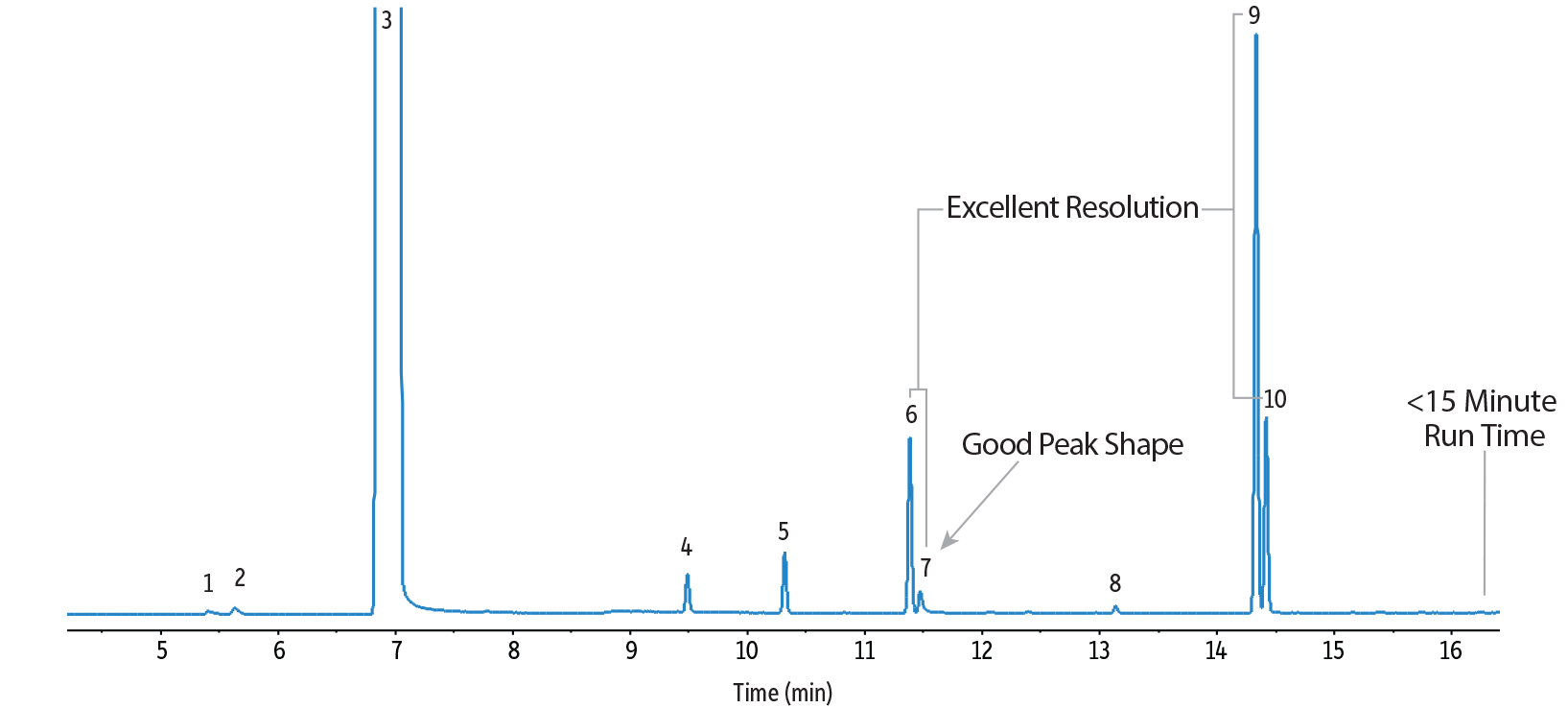

Figure 5: Rye whiskey by GC-FID on an Rtx-1301 column exhibits excellent resolution, satisfactory acetic acid peak shape, and a fast <15-minute analysis time.

GC_FF1395

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Acetaldehyde | 5.405 |

| 2. | Methanol | 5.631 |

| 3. | Ethanol | 7.032 |

| 4. | 1-Propanol | 9.489 |

| 5. | Ethyl acetate | 10.318 |

| 6. | Isobutanol | 11.385 |

| 7. | Acetic acid | 11.472 |

| 8. | Acetal | 13.137 |

| 9. | 3-Methyl-1-butanol | 14.334 |

| 10. | 2-Methyl-1-butanol | 14.419 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Rye whiskey (neat) |

| Diluent: | n/a |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz precision inlet liner, 4.0 mm x 6.3 x 78.5, with wool (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 144.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.457 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

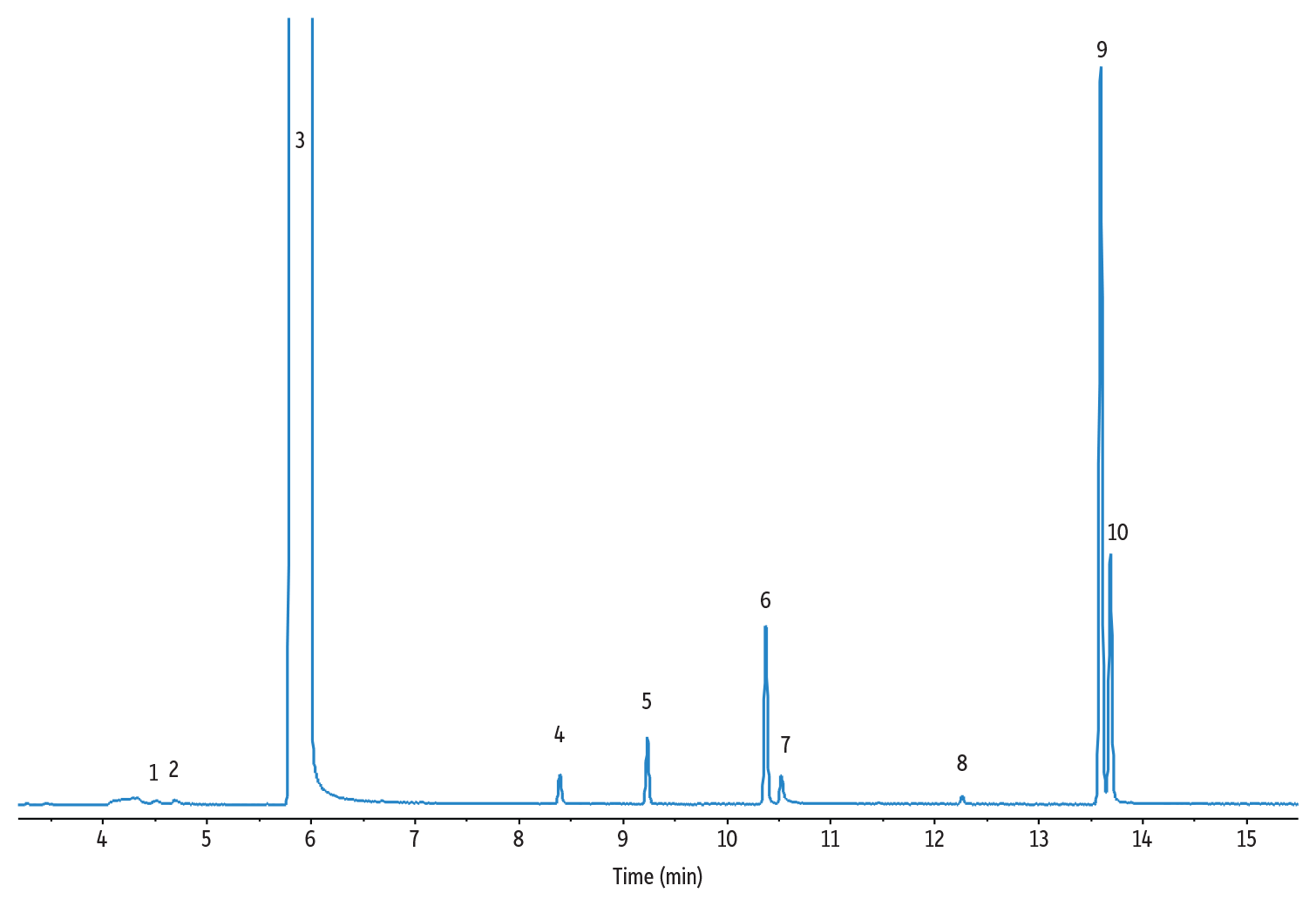

Figure 6: GC-MS analysis of rye whiskey shows the same chromatography as the GC-FID analysis in Figure 5.

GC_FF1396

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Acetaldehyde | 4.493 |

| 2. | Methanol | 4.684 |

| 3. | Ethanol | 5.988 |

| 4. | 1-Propanol | 8.392 |

| 5. | Ethyl acetate | 9.234 |

| 6. | Isobutanol | 10.373 |

| 7. | Acetic acid | 10.521 |

| 8. | Acetal | 12.265 |

| 9. | 3-Methyl-1-butanol | 13.595 |

| 10. | 2-Methyl-1-butanol | 13.667 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Rye whiskey |

| Diluent: | n/a |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz precision inlet liner w/wool, 4.0 mm x 6.3 x 78.5 (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 140 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 2.45 min) to 220 °C at 7 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 30.261 cm/sec @ 35 °C |

| Detector | MS |

|---|---|

| Mode: | Scan |

| Transfer Line Temp.: | 280 °C |

| Analyzer Type: | Quadrupole |

| Source Temp.: | 230 °C |

| Quad Temp.: | 150 °C |

| Electron Energy: | 70 eV |

| Solvent Delay Time: | 0.0 min |

| Tune Type: | PFTBA |

| Ionization Mode: | EI |

| Instrument | Agilent 7890A GC & 5975C MSD |

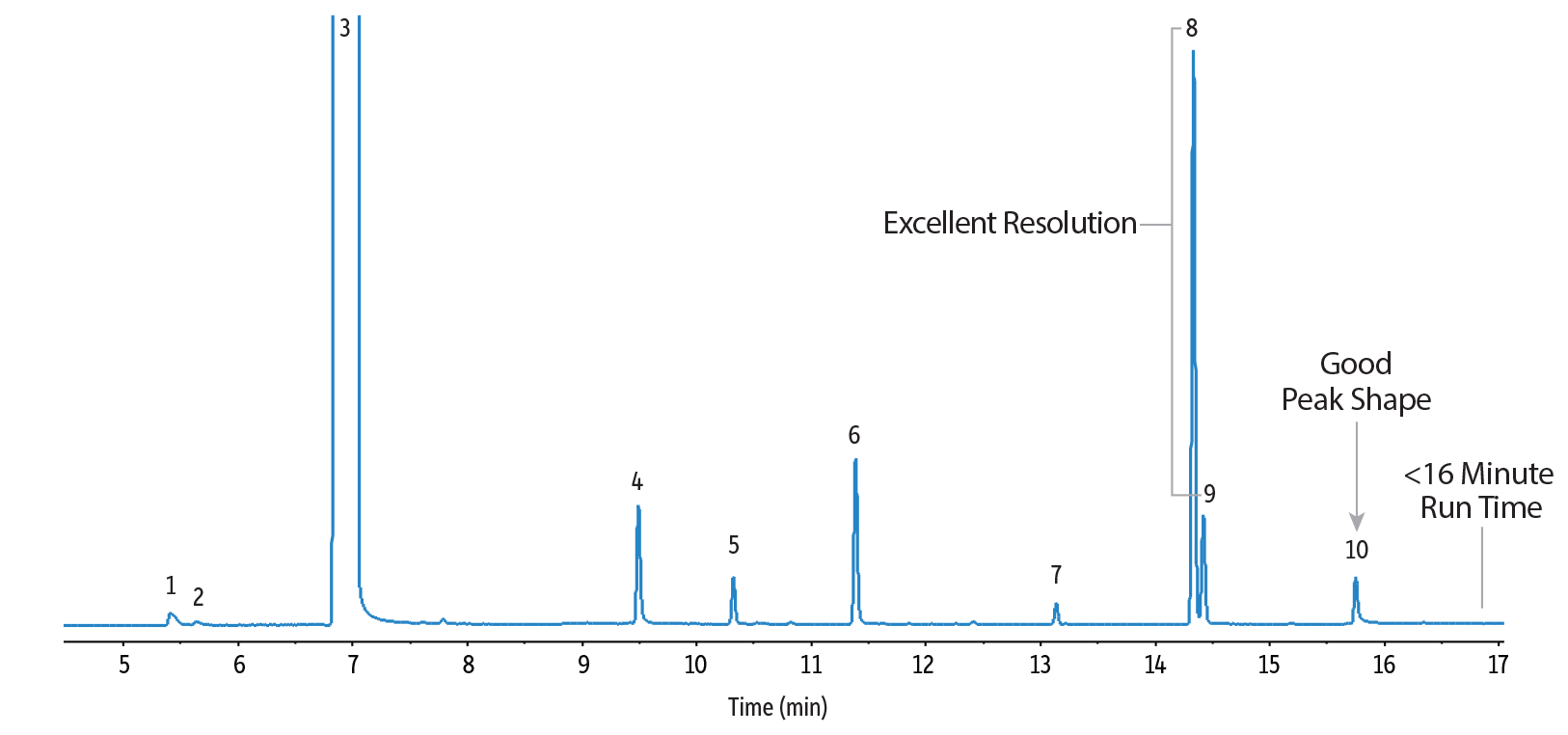

Additives are commonly encountered when analyzing liquors. In fact, up to 2% of any spirit can be unreported and not disclosed on the label, so unlabeled additives are frequently present. For example, propylene glycol and glycerin are sometimes added to liquor. Rum may have propylene glycol added to give the product a mouthfeel similar to an aged rum. Similarly, glycerin may be added for smoothness. Some of these compounds appeared in the range of liquors that were analyzed in Figures 7-11. Note that for these real-world samples, the Rtx-1301 column again provided excellent resolution of critical compounds, good peak shape for acetic acid, and fast analysis times, making it an outstanding column choice for alcoholic beverage analysis by GC.

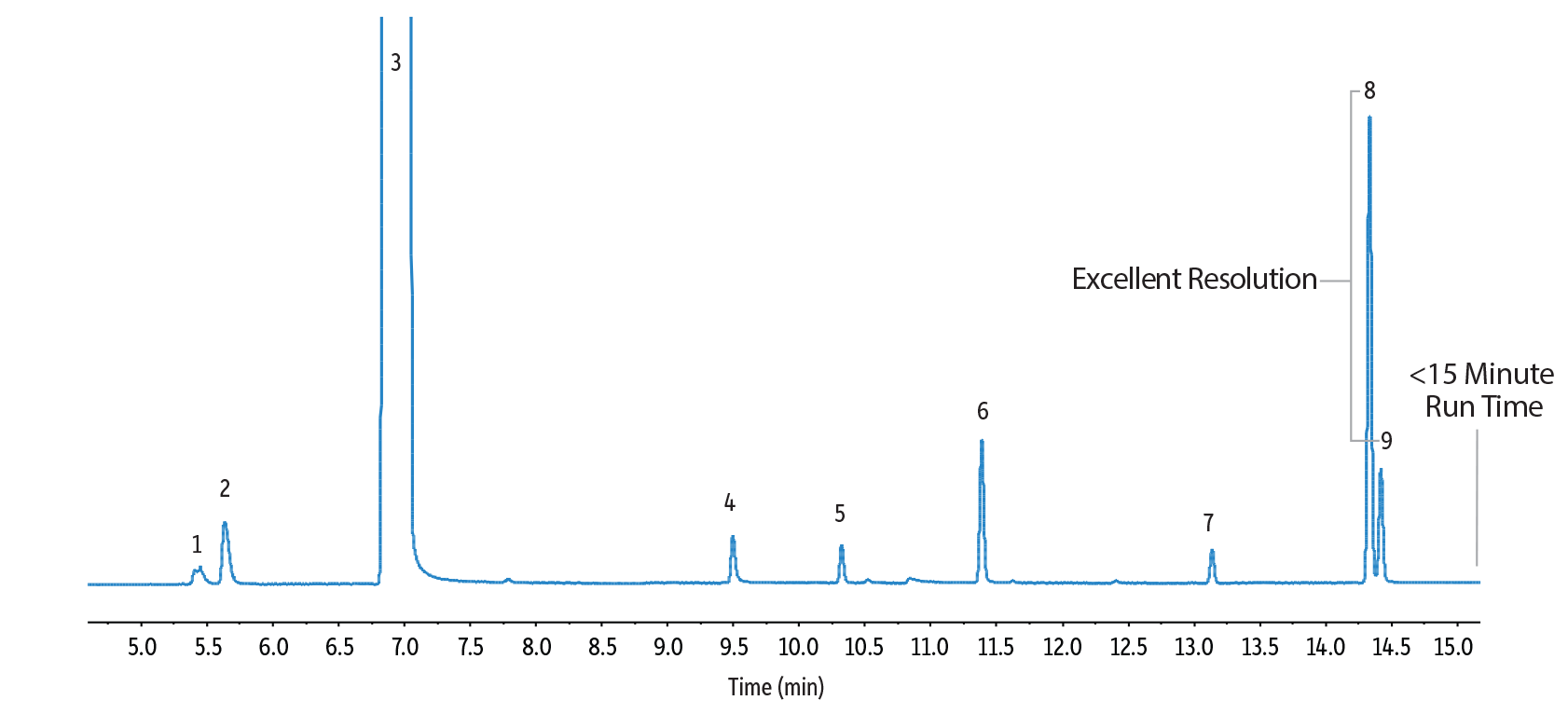

Figure 7: Brandy analysis using an Rtx-1301 column and GC-FID shows excellent resolution.

GC_FF1391

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Acetaldehyde | 5.449 |

| 2. | Methanol | 5.634 |

| 3. | Ethanol | 7.028 |

| 4. | 1-Propanol | 9.495 |

| 5. | Ethyl acetate | 10.321 |

| 6. | Isobutanol | 11.387 |

| 7. | Acetal | 13.137 |

| 8. | 3-Methyl-1-butanol | 14.333 |

| 9. | 2-Methyl-1-butanol | 14.420 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Brandy (neat) |

| Diluent: | n/a |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz precision inlet liner, 4.0 mm x 6.3 x 78.5, with wool (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 144.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.457 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

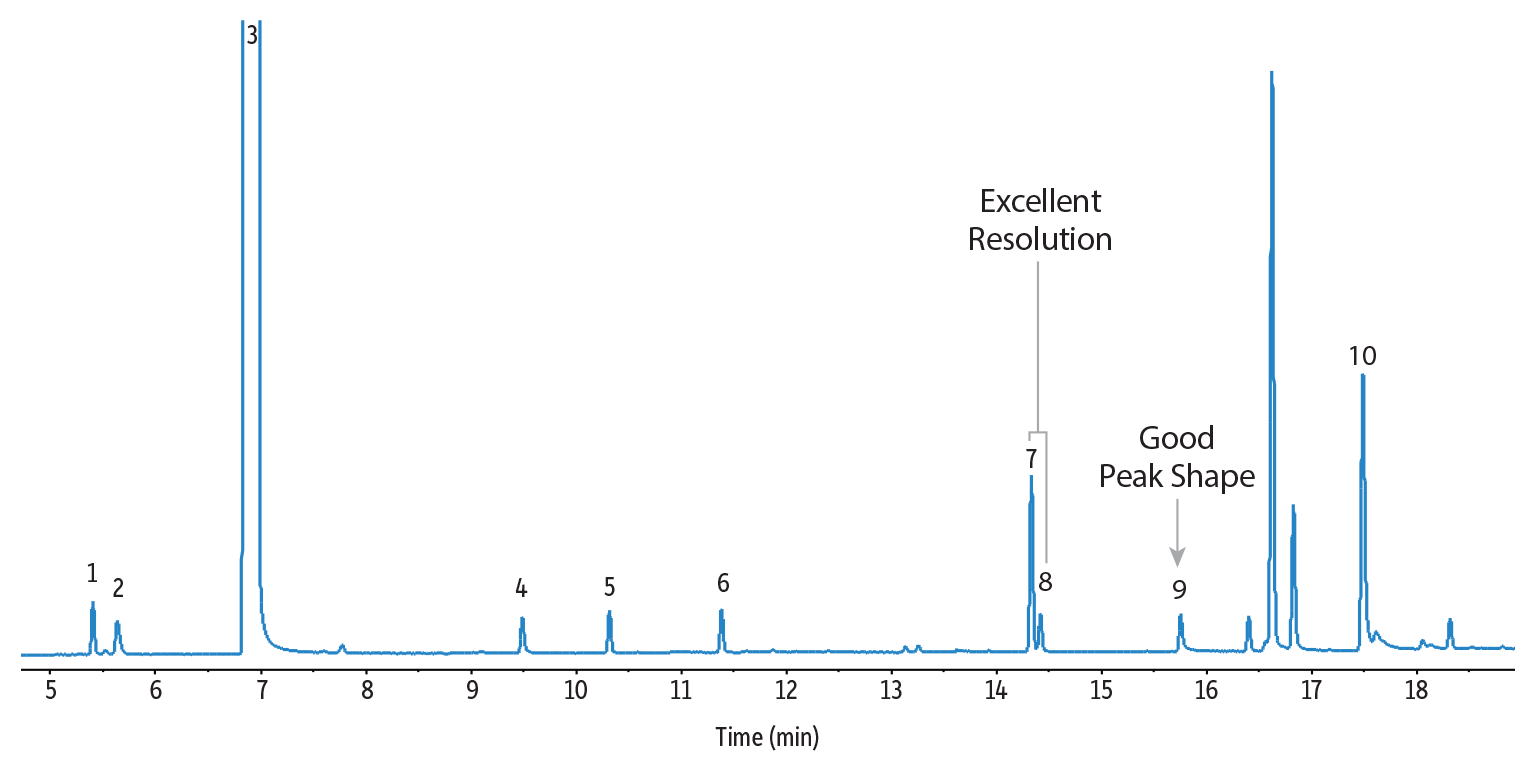

Figure 8: Sherry analysis using an Rtx-1301 column and GC-FID not only shows excellent resolution but also exhibits good peak shape for the additive propylene glycol.

GC_FF1392

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Acetaldehyde | 5.405 |

| 2. | Methanol | 5.636 |

| 3. | Ethanol | 6.963 |

| 4. | 1-Propanol | 9.490 |

| 5. | Ethyl acetate | 10.319 |

| 6. | Isobutanol | 11.385 |

| 7. | 3-Methyl-1-butanol | 14.333 |

| 8. | 2-Methyl-1-butanol | 14.419 |

| 9. | Propylene glycol | 15.752 |

| 10. | Furfural | 17.486 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Sherry (neat) |

| Diluent: | n/a |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz precision inlet liner, 4.0 mm x 6.3 x 78.5, with wool (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 144.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.457 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

Figure 9: Irish whiskey analysis using an Rtx-1301 column and GC-FID shows good resolution and a <15-minute analysis time.

GC_FF1393

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Acetaldehyde | 5.410 |

| 2. | Methanol | 5.638 |

| 3. | Ethanol | 7.029 |

| 4. | 1-Propanol | 9.492 |

| 5. | Ethyl acetate | 10.322 |

| 6. | Isobutanol | 11.388 |

| 7. | Acetal | 13.137 |

| 8. | 3-Methyl-1-butanol | 14.334 |

| 9. | 2-Methyl-1-butanol | 14.420 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Irish whiskey |

| Diluent: | n/a |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz precision split liner, 4.0 mm x 6.3 x 78.5, with wool (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 144.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.457 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

Figure 10: Marsala analysis using an Rtx-1301 column and GC-FID shows good resolution.

GC_FF1394

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Acetaldehyde | 5.404 |

| 2. | Methanol | 5.632 |

| 3. | Ethanol | 6.956 |

| 4. | Ethyl formate | 7.779 |

| 5. | 1-Propanol | 9.485 |

| 6. | Ethyl acetate | 10.318 |

| Peaks | tR (min) | |

|---|---|---|

| 7. | sec-Butanol | 10.507 |

| 8. | Isobutanol | 11.384 |

| 9. | Acetic acid | 11.479 |

| 10. | Acetal | 13.143 |

| 11. | 3-Methyl-1-butanol | 14.333 |

| 12. | 2-Methyl-1-butanol | 14.419 |

| 13. | Furfural | 17.491 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Marsala (neat) |

| Diluent: | n/a |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz precision inlet liner, 4.0 mm x 6.3 x 78.5, with wool (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 144.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.457 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

Figure 11: Rum analysis using an Rtx-1301 column and GC-FID shows good resolution and good peak shape for the additive propylene glycol.

GC_FF1390

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Acetaldehyde | 5.410 |

| 2. | Methanol | 5.634 |

| 3. | Ethanol | 7.026 |

| 4. | 1-Propanol | 9.492 |

| 5. | Ethyl acetate | 10.321 |

| 6. | Isobutanol | 11.387 |

| 7. | Acetal | 13.138 |

| 8. | 3-Methyl-1-butanol | 14.334 |

| 9. | 2-Methyl-1-butanol | 14.420 |

| 10. | Propylene glycol | 15.749 |

Conditions

| Column | Rtx-1301, 60 m, 0.25 mm ID, 1.0 µm (cat.# 16056) |

|---|---|

| Standard/Sample | Rum (neat) |

| Diluent: | n/a |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 100:1) |

| Liner: | Topaz, precision inlet liner, 4.0 mm x 6.3 x 78.5, with wool (cat.# 23305) |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 144.4 mL/min |

| Oven | |

| Oven Temp.: | 35 °C (hold 3 min) to 220 °C at 8 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.4 mL/min |

| Linear Velocity: | 25.457 cm/sec @ 35 °C |

| Detector | FID @ 250 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 35 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

Meet the Experts

| Corby Hilliard As an advanced scientist in Restek’s GC lab with over 20 years of experience, Corby’s focus is on generating methodology and application data predominately for the food, petrochemical, and environmental industries. He is also involved with R&D and new product development. |

| Carolyn King Carolyn is currently a technical service specialist at Restek. She began her career in 2012 in the QC lab conducting testing to ensure product quality before joining the technical service group in 2015. Carolyn holds a BS in animal sciences and nutritional sciences from The Pennsylvania State University. |

References

- AOAC International, AOAC Official methods of analysis, 22nd edition, Edited by George W. Latimer, Jr., 3 vols., Oxford University Press, Oxford, UK, 2023.