- Economical, continuous source of ultra-pure hydrogen (99.9995%).

- Safe and easy to use and maintain.

- Hydrogen reduces gas costs, cuts analysis time by 50%, increases column lifetimes.

If you use 2-3 cylinders of helium and/or hydrogen per week, as carrier gas and/or fuel gas, bottled gas is an expense in the range of $12,000 to $25,000 per year*, including overhead: expenses and time involved with ordering, transporting, installing, and periodically inspecting cylinders. You also contend with unquantifiable costs, such as floor space lost to an inventory of cylinders. Helium, widely used as carrier gas, is a non renewable resource extracted from natural gas and, because it is a petrochemical product, its cost will continue to rise, domestically and internationally. Chromatographers must look for cost-effective, ultra-pure gas alternatives to supply their instruments and state-of-the-art analytical columns. Fortunately, we do have options.

Past practice in gas chromatography was to select either nitrogen or helium as the carrier gas. Hydrogen wasn’t given much consideration, primarily because of flammability and storage issues, even though it offers several distinct advantages over nitrogen or helium. Now, Parker hydrogen generators offer a safe, reliable source of ultra-pure (99.9995%) hydrogen, and effective replacements for bottled gas. A Parker hydrogen generator stores less than 50mL of hydrogen (less than 0.002 cubic feet) at 1 atm., or 305 mL of hydrogen (0.01 cubic feet) at 6.1 atmospheres (90 psig.) From a safety standpoint there is no compromise, compared to a 300 cubic foot cylinder of hydrogen at 2500 psig.

Parker hydrogen generators continuously produce dry, ultra-pure hydrogen by electrolytic dissociation of deionized water and hydrogen proton conduction across a membrane. The hydrogen product is dried by passing it through a coalescing filter, a drying tube, and a desiccant cartridge. Maximum output pressure, 90psig, is controlled to the point of use via a pressure adjust regulator. Other safety features include a pressure relief valve to prevent overpressurization and a mass leak sensor to indicate hydrogen demand is exceeding instrument capability, in which case the generator will shut down. A low water level and/or poor quality water also will shut down the generator, to prevent damage to the electrolytic cell.

Maintaining the generator is simple. Deionized water is all that is required for weeks of continuous operation. Simply change the filters every six months and the desicant cartridge when it changes from beige to clear.

To evaluate performance, we set up a small Parker hydrogen generator (90mL/min. maximum hydrogen output) to supply both carrier gas and fuel gas to an Agilent 6890 GC. We installed a 30 meter x 0.53 mm ID x 5 µm df Rtx-1 column (100% polydimethylsiloxane (PDMS) phase, cat.# 10179) in the oven and set analytical parameters as specified in a simulated distillation method, ASTM D-7096-05, but substituted hydrogen for helium as the carrier gas. We used a column flow rate of 40 mL/min., in the constant flow mode, which represented the optimum linear velocity for hydrogen. The 40 mL/min. carrier gas flow rate, plus a 40 mL/min. flow of fuel gas, was 90% of the generator’s maximum output capacity, and tested the generator’s capability to meet volume demands.

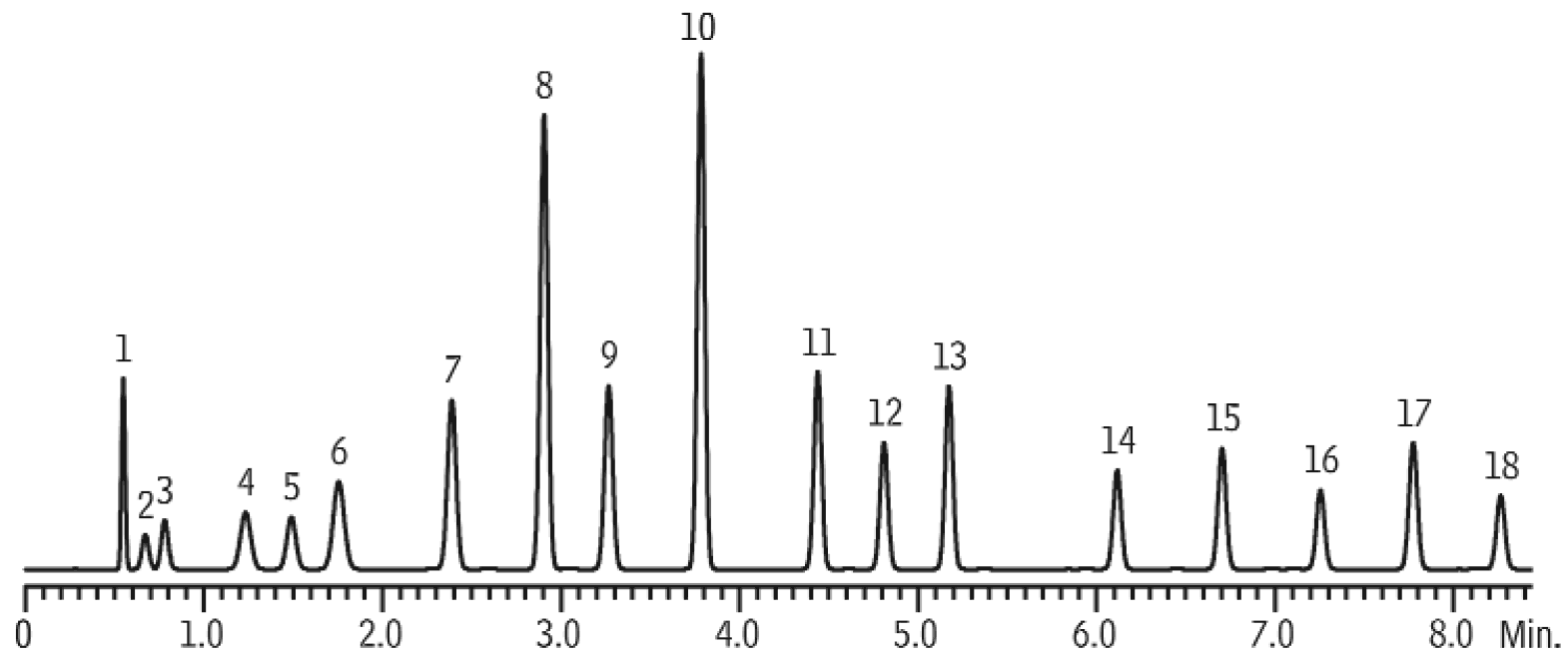

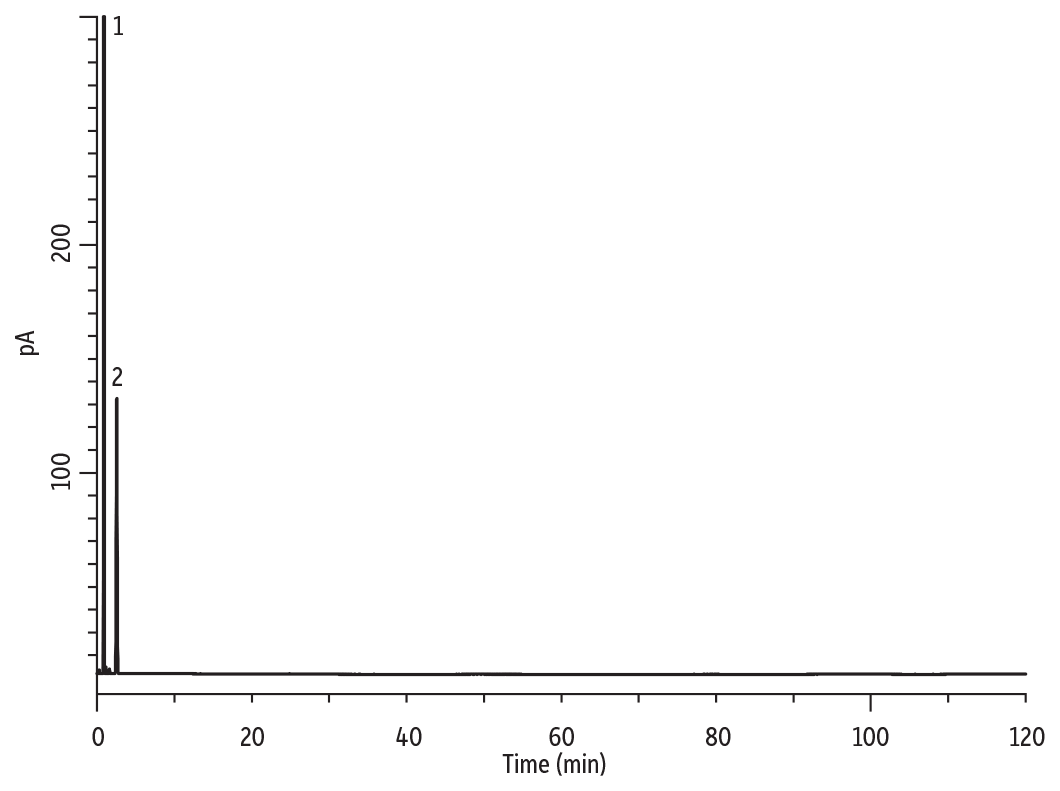

Figure 1 is a chromatogram of the calibration standard used for retention time-boiling point determination and response factor validation in the ASTM method. The components were well resolved and the analysis completed rapidly, in little more than 8 minutes. Reproducible retention times are vital to obtaining accurate initial boiling point (IBP) data. Table 1 shows retention times for the ASTM reference mix components were well-within the method specification of ±0.05 minutes per compound, demonstrating the hydrogen generator’s ability to maintain a steady and precise flow of carrier gas. Figure 2 monitors FID baseline stability over 2 hours. These figures and data clearly show that a Parker hydrogen generator is a dependable source of ultra-high purity carrier and fuel gas for demanding GC applications.

On average, yearly electricity and maintenance costs for operating a Parker hydrogen generator are approximately $350*. Offsetting the costs of purchasing and operating a generator with the savings made by not using gas cylinders indicates the generator will pay for itself in 1 to 2 years. With numbers like these, can you afford not to consider purchasing a Parker hydrogen generator for your laboratory?

Table 1: Repeatable retention times for simulated distillation mix components confirm the hydrogen generator’s steady and precise flow of carrier gas.

| Component | Run Number / Retention Time (min.) | ||||||||

| Mean | SD | %RSD | 1 | 2 | 3 | 4 | 5 | 6 | |

| 1. ethanol | 0.547 | 1E-03 | 0.1765 | 0.546 | 0.548 | 0.548 | 0.548 | 0.549 | |

| 2. isopentane | 0.67 | 1E-03 | 0.1484 | 0.669 | 0.67 | 0.671 | 0.67 | 0.672 | |

| 3. n-pentane | 0.779 | 0.001 | 0.169 | 0.777 | 0.779 | 0.78 | 0.779 | 0.781 | |

| 4. 2-methylpentane | 1.232 | 0.001 | 0.1198 | 1.229 | 1.231 | 1.233 | 1.232 | 1.234 | |

| 5. n-hexane | 1.488 | 0.001 | 0.0992 | 1.485 | 1.487 | 1.489 | 1.488 | 1.49 | |

| 6. 2,4-dimethylpentane | 1.753 | 0.001 | 0.0721 | 1.751 | 1.752 | 1.754 | 1.754 | 1.755 | |

| 7. n-heptane | 2.387 | 0.001 | 0.0442 | 2.385 | 2.386 | 2.388 | 2.387 | 2.388 | |

| 8. toluene | 2.904 | 0.001 | 0.0356 | 2.902 | 2.904 | 2.905 | 2.904 | 2.905 | |

| 9. n-octane | 3.266 | 7E-04 | 0.0214 | 3.264 | 3.265 | 3.266 | 3.266 | 3.266 | |

| 10. p-xylene | 3.784 | 7E-04 | 0.0195 | 3.783 | 3.784 | 3.785 | 3.784 | 3.784 | |

| 11. n-propylbenzene | 4.438 | 5E-04 | 0.0109 | 4.437 | 4.438 | 4.438 | 4.438 | 4.438 | |

| 12. n-decane | 4.809 | 4E-04 | 0.0088 | 4.809 | 4.809 | 4.809 | 4.809 | 4.809 | |

| 13. butylbenzene | 5.174 | 5E-04 | 0.0102 | 5.173 | 5.174 | 5.174 | 5.174 | 5.173 | |

| 14. n-dodecane | 6.116 | 5E-04 | 0.0079 | 6.116 | 6.116 | 6.116 | 6.116 | 6.116 | |

| 15. n-tridecane | 6.703 | 5E-04 | 0.0077 | 6.704 | 6.704 | 6.704 | 6.704 | 6.703 | |

| 16. n-tetradecane | 7.255 | 7E-04 | 0.0097 | 7.256 | 7.255 | 7.255 | 7.255 | 7.254 | |

| 17. n-pentadecane | 7.774 | 6E-04 | 0.0081 | 7.775 | 7.775 | 7.775 | 7.774 | 7.774 | |

| 18. n-hexadecane | 8.264 | 6E-04 | 0.0069 | 8.265 | 8.265 | 8.264 | 8.264 | 8.264 | |

Figure 1: A simulated distillation reference mix is well resolved, in 8 minutes, showing a Parker hydrogen generator can meet gas volume demands.

GC_PC00852

Peaks

| Peaks | |

|---|---|

| 1. | Ethanol |

| 2. | iso-Pentane |

| 3. | n-Pentane |

| 4. | 2-Methylpentane |

| 5. | n-Hexane |

| 6. | 2,4-Dimethylpentane |

| 7. | n-Heptane |

| 8. | Toluene |

| 9. | n-Octane |

| Peaks | |

|---|---|

| 10. | p-Xylene |

| 11. | n-Propylbenzene |

| 12. | n-Decane |

| 13. | Butylbenzene |

| 14. | n-Dodecane |

| 15. | n-Tridecane |

| 16. | n-Tetradecane |

| 17. | n-Pentadecane |

| 18. | n-Hexadecane |

Conditions

| Column | Rtx-1, 30 m, 0.53 mm ID, 5.0 µm (cat.# 10179) |

|---|---|

| Standard/Sample | Custom paraffin mix, neat, 2.7-12.9% each component |

| Injection | |

| Inj. Vol.: | 0.1 µL splitless (hold 1 min) |

| Liner: | 4 mm single taper inlet liner |

| Inj. Temp.: | 250 °C |

| Oven | |

| Oven Temp.: | 40 °C (hold 1 min) to 265 °C at 25 °C/min (hold 4 min) |

| Carrier Gas | H2, constant linear velocity |

| Linear Velocity: | 184 cm/sec @ 40 °C |

| Detector | FID @ 280 °C |

|---|---|

| Notes | Liner cat.# 20904 was used to produce this chromatogram, but has since been discontinued. For assistance choosing a replacement for this application, contact Restek Technical Service or your local Restek representative. – – – – – – Using Parker ChromGas hydrogen generator |

Figure 2: Carrier gas from a Parker hydrogen generator assures a stable baseline, for sensitive analyses. Performance equivalent to cylinders, at lower cost.

GC_PC00853

Peaks

| Peaks | |

|---|---|

| 1. | Solvent |

| 2. | n-Tridecane |

Conditions

| Column | Rtx-1, 30 m, 0.53 mm ID, 5.00 µm (cat.# 10179) |

|---|---|

| Standard/Sample | Custom n-tridecane mix |

| Diluent: | Methylene chloride |

| Conc.: | 1 µg/mL |

| Injection | |

| Inj. Vol.: | 0.1 µL splitless (hold 1 min) |

| Liner: | 4 mm Splitless |

| Inj. Temp.: | 250 °C |

| Oven | |

| Oven Temp.: | 40 °C (hold 120 min) |

| Carrier Gas | H2, constant flow |

| Linear Velocity: | 184 cm/sec |

| Detector | FID @ 280 °C |

|---|---|

| Notes | Liner cat.# 20904 was used to produce this chromatogram, but has since been discontinued. For assistance choosing a replacement for this application, contact Restek Technical Service or your local Restek representative. – – – – – – Carrier Gas: Parker hydrogen generator @ 40° C. Constant flow determined at 40° C. |

Footnote

- Cost estimate for U.S., in U.S. $, 2021.

- ** For for more information on ASTM-D-7096-05, visit our ASTM Petrochemical Method Chromatography Product Guide