When talking with customers, I always hear there is a lot of interest in doing faster GC. Often people think they have to buy new instrumentation to do that. Sometimes it’s necessary if you have a 20 year old GC, but for most GC’s of younger age, you can easily develop method to go faster. What you need to know is what your objectives are.

There are roughly 2 situations:

- We have plenty of resolution between the components of interest. Here we trade some efficiency in favor for a faster analysis

- We have “just” enough resolution. Here we need for the faster solution at least similar efficiency (plate number).

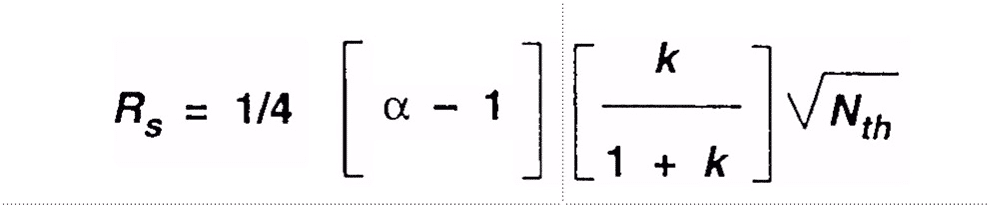

Fig. 1 generalized resolution equation

In the first case we can manipulate several parameters to reduce the analysis time. Let’s first take a look at the column dimensions.

As we have plenty of resolution, we should be able to choose a column with less separation power. The most easy is to use a shorter column length. Looking at the resolution equation in fig.1, we see the resolution is linear to the square of the plate number. This means that when I reduce the column length by a factor 2, the resolution only reduces by a factor 1.4. The analysis time however reduces immediately by a factor 2.

Fig.2 Comparison of analysis time of a 60 and a 30m column; Isothermal analysis on Rt Alumina BOND. The 30m is 2x faster.

Fig 2 shows the effect of length on analysis time using a 60 and a 30 m Rt Alumina BOND column. The alumina BOND is very selective for C1-C5 hydrocarbons, meaning that the components are all very well resolved. The analysis was done in the same GC, same carrier gas and the result shows a very simple reduction of analysis time by a factor 2.

By changing ONLY the column length, the only change we had to make was setting a lower inlet pressure. Very easy to implement for isothermal methods.

For temperature programmed methods, we have to adjust besides the inlet pressure, also the temperature program rate and the iso times. Reason for this is, that we like to have exactly the SAME separation. This only happens if the elution temperatures are kept the same.

If we reduce the column length by a factor 2, we need to increase the program rate by a factor 2 and decrease the iso-times by a factor 2. Example calculation is shown in figure 3. When we make these changes, we also will get exactly a factor 2 shorter run time while elution temperatures remain the same.

This can be done basically for all methods where there is plenty of resolution. The limitation is usually set by the maximum temperature program the oven can accommodate. Most GC’s can program with 25-30C/min, but above 200C it becomes difficult. One can make the GC keep up with the higher temperature program rates by using a 220V OR using an oven –insert.. By reducing the oven size, the systems can heat up much faster.

Fig.3 Example of new temperature program when replacing a 30m for a 15 m column: elution temperatures will be similar resulting in same chromatogram, just 2x faster

To produce less plates one can also use a wider diameter column of same or shorter length, or use a much shorter column with smaller diameter. Choosing the wider diameter in shorter length will also be an option, but we have to be more careful with adjusting pressures and oven programming-rate. The much shorter smaller ID column will be faster, but will also challenge the method on setting of operational parameters like pressures, program rates, injection speed and loadability. We will discuss this one later if we are going for speeding up situation 2.

Next time we will discuss how we manipulate run time using flow..