Living in Pennsylvania during this natural gas boom stirs passionate, mixed emotions about the economic benefits verses the environmental costs of drilling for this resource.

When the Marcellus Shale natural gas drilling in Pennsylvania really started taking off several years ago, we (tech service) were taking quite a few calls about analyzing C1 through C4 (methane through butane) in water samples. Many of our customers had tried this analysis using their purge & trap (p&t) instruments without success, because the only available traps on the market at that time were not capable of trapping methane. As a result, the only two ways I knew how to do this analysis were to use either headspace or liquid injections. Several years later, Teledyne Tekmar published an application note using p&t titled Alternative Methods to RSK 175 Using Purge and Trap Concentration and Automated Headspace for the Analysis of Dissolved Gases in Drinking Water.

Now, for the first time, I have seen a published method using purge & trap (PA-DEP 9243, link below).

Light Hydrocarbons in Aqueous Samples via Purge and Trap

So, how well does this method work? I have no idea, but if someone out there has tried it, I would like to hear back from you.

(Note – I did find a typo in the method; the Restek U-Bond PLOT column they mentioned should be listed with a 20µmdf film-thickness (not 0.2µmdf). The Restek catalog number for this column is 19749. The catalog number for the ShinCarbon column is 19809.)

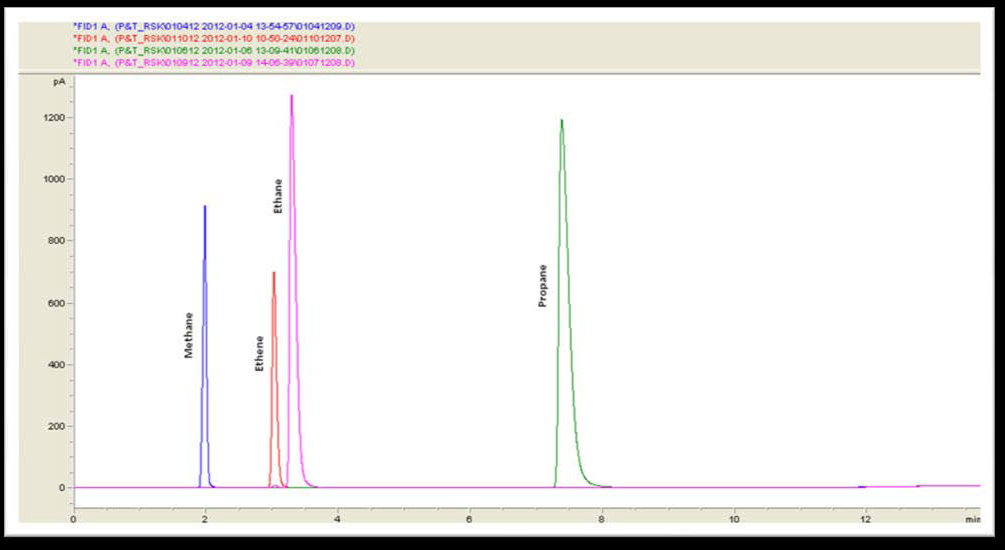

Chromatogram above from Teledyne Tekmar using the Restek U-Bond.

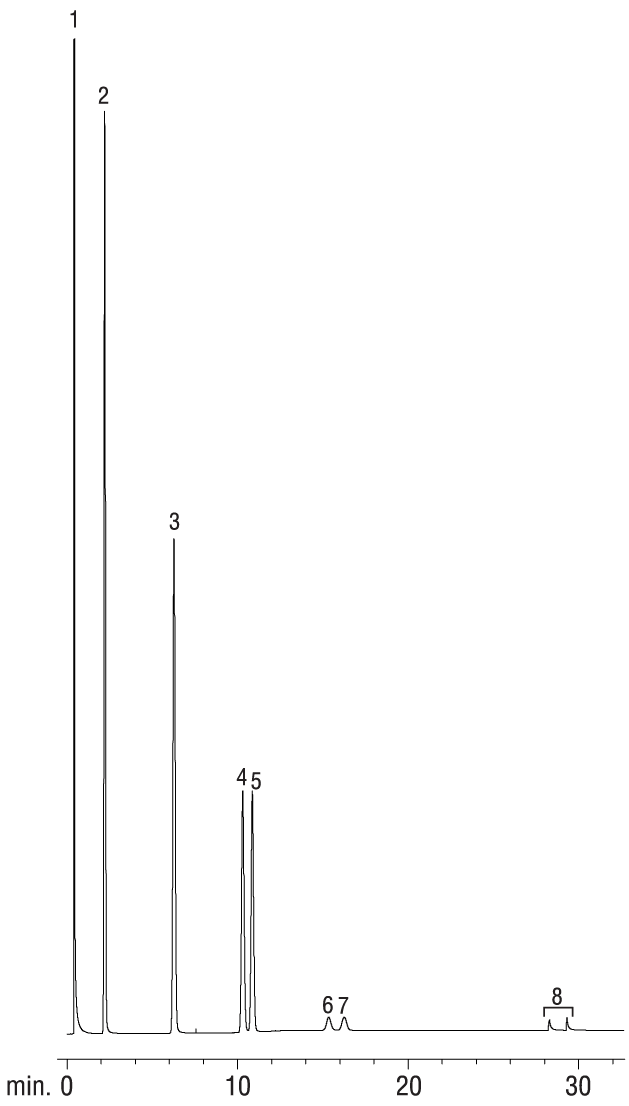

Natural Gas ShinCarbon ST (Micropacked)

GC_PC00672

Conditions

| Column | 100/120 mesh on ShinCarbon ST, SilcoSmooth tubing, 1 m, 1/16 OD, 1.0 mm ID (cat.# 19809) |

|---|---|

| Standard/Sample | C1-C6 hydrocarbons |

| Conc.: | 0.5-8% varied |

| Injection | packed on-column |

| Inj. Temp.: | 200 °C |

| Oven | |

| Oven Temp.: | 125 °C to 250 °C at 16 °C/min (hold 25.2 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 10 mL/min |

| Detector | FID @ 250 °C |

|---|

As a final note, I would like to thank co-workers Chris English for a previous post which laid the groundwork for this post, and Chris Rattray for contacting Teledyne Tekmar to confirm that the trap used in this method was their proprietary trap P/N: 15-0885-403.