In my previous blog on cryogenic cooling I touched briefly on ethylene oxide (EtO) and why it may be of interest in ambient air analysis. While OSHA has a time weighted average (TWA) limit for EtO at 1ppm for an 8 hour exposure, recent work by the US EPA has shown that even low doses of ethylene oxide can increase cancer risks over a person’s lifetime (https://cfpub.epa.gov/ncea/iris/iris_documents/documents/toxreviews/1025tr.pdf), which explains the interest in testing for EtO at sub ppb levels. Since this brings EtO testing to similar levels as TO-15A, why not combine the two?

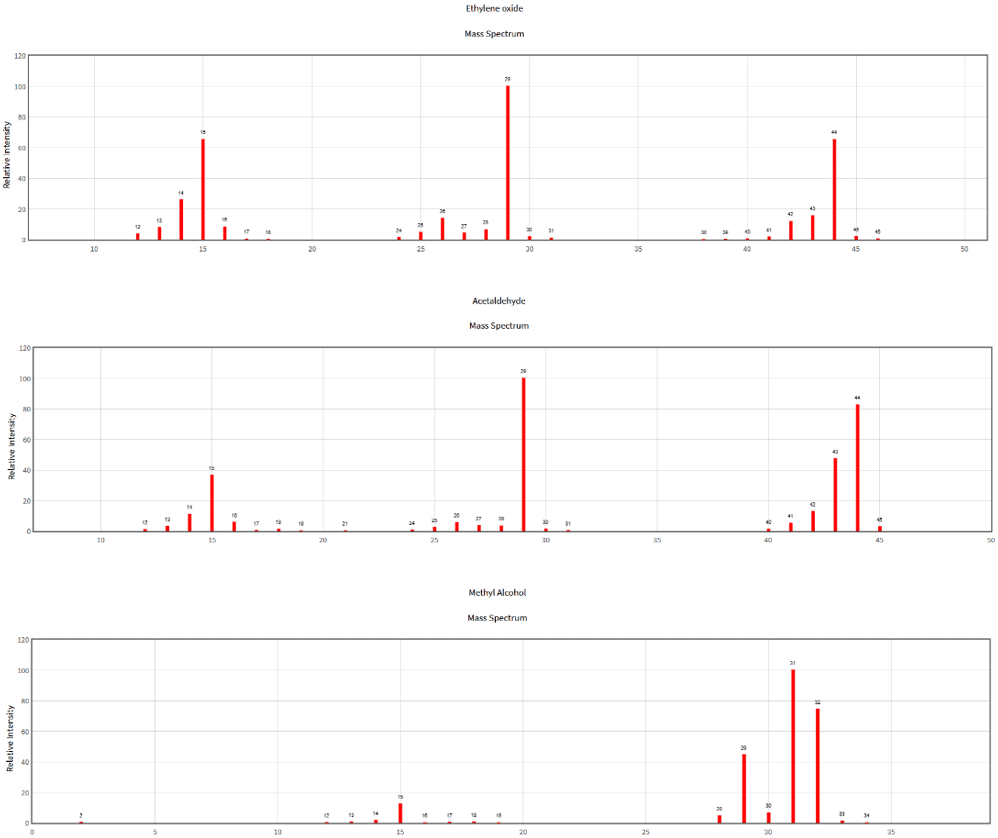

While my previous blog covered the need to separate EtO from the air peaks introduced into the instrument, there are several other potential interferences that have to be managed. Acetaldehyde has an almost identical structure and mass spectrum. It is very common in nature and produced in a wide variety of industries, and it is possible to be present in both lab blanks and samples. Methanol also shares several ions with EtO, and as a common solvent for volatile standards (e.g., 8260 and TO-15A internal standards) it’s likely present in most air labs.

Fig. 1 – Comparison of EtO, Acetaldehyde, and methanol mass spectrum

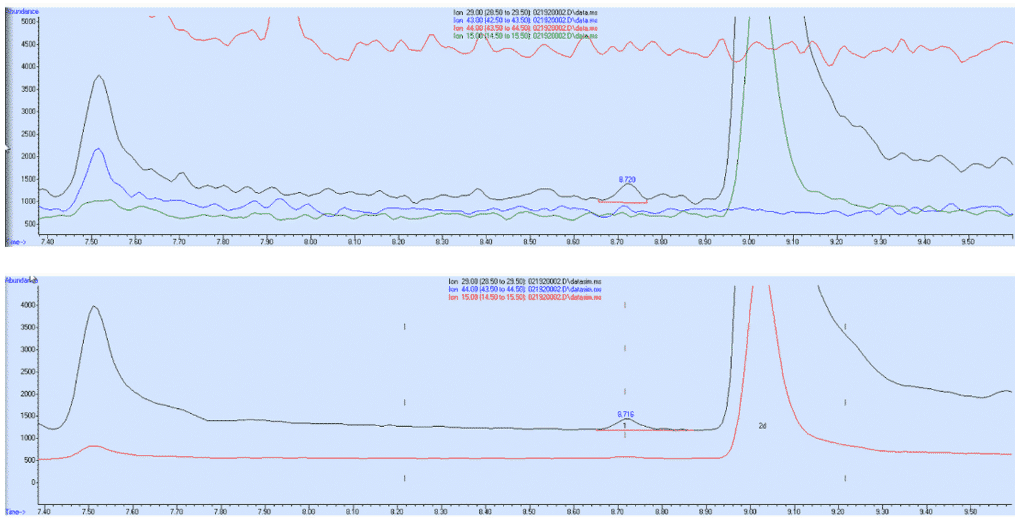

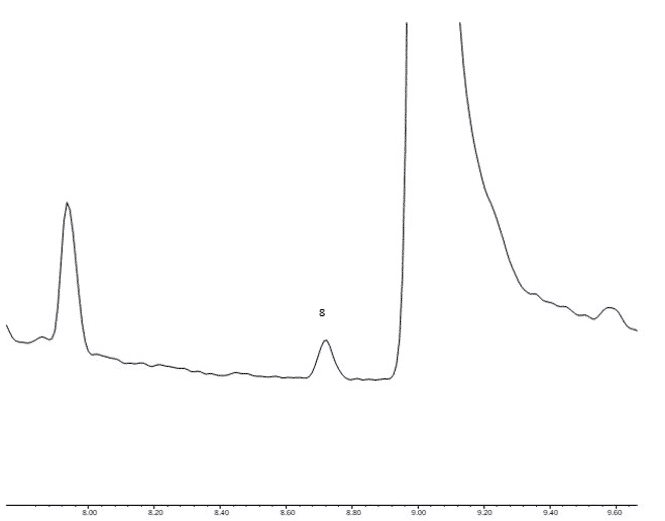

Fortunately the cryo cooling helps with these separations as well. In addition, I also found that using selected ion monitoring (SIM) produced a cleaner baseline and better signal to noise ratio, allowing for detection of EtO down to 0.05ppb or lower (Fig.2 lower trace).

Fig. 2 – Comparison of Scan (top) and SIM (bottom) signals for EtO (RT ~8.72) with acetaldehyde (RT ~7.50) and MeOH (RT ~9.00) interferences. EtO at 0.05ppb

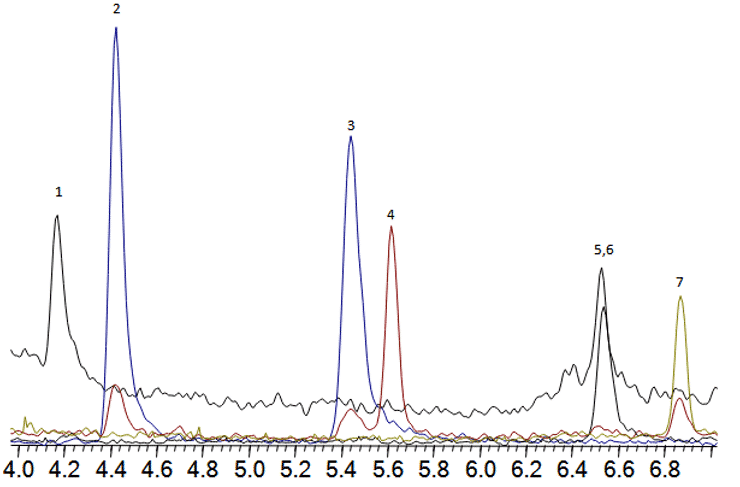

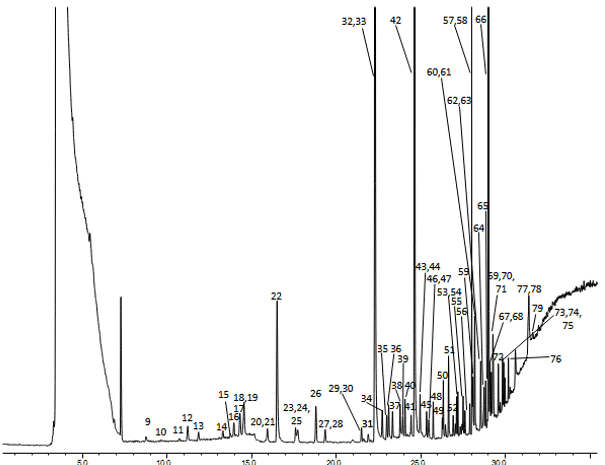

Once the troublesome EtO/acetaldehyde/methanol separations are solved with cryo cooling, I was able to use EZGC to get a working oven program to separate the TO-15A compound list. Without the need for extra sensitivity on the TO-15A compounds I found it helpful to use the combined SIM/Scan capabilities of the Agilent 5977A mass spec, using the SIM data for EtO and the scan data for the TO-15A list. This meant I didn’t have to optimize the SIM parameters for nearly 80 compounds, keeping the method much simpler.

Fig. 3 – Combined TO-15A and EtO chromatogram with EIC for compounds 1-7 (top), SIM for EtO ( compound 8, middle), and TIC (compounds 9-79, bottom). TO-15A compounds at 0.2ppb, EtO at 0.05ppb.

| # | Name | Ret Time |

| 1 | Propylene | 4.17 |

| 2 | Dichlorodifluoromethane | 4.43 |

| 3 | 1,2-Dichlorotetrafluoroethane | 5.45 |

| 4 | Chloromethane | 5.62 |

| 5 | n-Butane | 6.52 |

| 6 | Vinyl chloride | 6.54 |

| 7 | 1,3-Butadiene | 6.87 |

| 8 | Ethylene Oxide | 8.72 |

| 9 | Bromomethane | 8.75 |

| 10 | Chloroethane | 9.64 |

| 11 | Vinyl bromide | 10.71 |

| 12 | Trichlorofluoromethane | 11.21 |

| 13 | n-Pentane | 11.85 |

| 14 | Ethanol | 13.29 |

| 15 | Acrolein | 13.74 |

| 16 | 1,1-Dichloroethene | 13.94 |

| 17 | 1,1,2-Trichlorotrifluoroethane | 14.3 |

| 18 | Carbon disulfide | 14.49 |

| 19 | Acetone | 14.55 |

| 20 | Acetonitrile | 15.83 |

| 21 | Isopropyl alcohol | 15.92 |

| 22 | Methylene chloride | 16.5 |

| 23 | trans-1,2-Dichloroethene | 17.6 |

| 24 | Tertiary butanol | 17.67 |

| 25 | Methyl tert-butyl ether (MTBE) | 17.73 |

| 26 | Hexane | 18.8 |

| 27 | 1,1-Dichloroethane | 19.35 |

| 28 | Vinyl acetate | 19.65 |

| 29 | cis-1,2-Dichloroethene | 21.49 |

| 30 | 2-Butanone (MEK) | 21.62 |

| 31 | Ethyl acetate | 21.9 |

| 32 | Bromochloromethane | 22.29 |

| 33 | Tetrahydrofuran | 22.35 |

| 34 | Chloroform | 22.74 |

| 35 | 1,1,1-Trichloroethane | 23 |

| 36 | Cyclohexane | 23.12 |

| 37 | Carbon tetrachloride | 23.35 |

| 38 | Benzene | 23.8 |

| 39 | 1,2-Dichloroethane | 23.96 |

| 40 | Isooctane | 24.09 |

| 41 | Heptane | 24.45 |

| 42 | 1,4-Difluorobenzene | 24.66 |

| 43 | Trichloroethylene | 24.98 |

| 44 | 1,1,2-Trichloroethane | 24.98 |

| 45 | 1,2-Dichloropropane | 25.36 |

| 46 | Methyl methacrylate | 25.49 |

| 47 | 1,4-Dioxane | 25.49 |

| 48 | Bromodichloromethane | 25.75 |

| 49 | cis-1,3-Dichloropropene | 26.28 |

| 50 | 4-Methyl-2-2pentanone (MIBK) | 26.46 |

| 51 | Toluene | 26.64 |

| 52 | trans-1,3-Dichloropropene | 26.91 |

| 53 | Tetrachloroethene | 27.18 |

| 54 | 2-Hexanone (MBK) | 27.32 |

| 55 | Dibromochloromethane | 27.49 |

| 56 | 1,2-Dibromoethane | 27.6 |

| 57 | Chlorobenzene-d5 | 28.02 |

| 58 | Chlorobenzene | 28.04 |

| 59 | Ethylbenzene | 28.11 |

| 60 | n-Nonane | 28.2 |

| 61 | m- & p-Xylene | 28.22 |

| 62 | o-Xylene | 28.55 |

| 63 | Styrene | 28.56 |

| 64 | Bromoform | 28.74 |

| 65 | Cumene | 28.83 |

| 66 | 4-Bromofluorobenzene | 28.99 |

| 67 | 1,1,2,2-Tetrachloroethane | 29.08 |

| 68 | n-Propyl benzene | 29.16 |

| 69 | 4-Ethyltoluene | 29.24 |

| 70 | 2-Chlorotoluene | 29.25 |

| 71 | 1,3,5-Trimethylbenzene | 29.28 |

| 72 | 1,2,4-Trimethylbenzene | 29.57 |

| 73 | 1,3-Dichlorobenzene | 29.82 |

| 74 | 1,4-Dichlorobenzene | 29.89 |

| 75 | Benzyl chloride | 29.97 |

| 76 | 1,2-Dichlorobenzene | 30.17 |

| 77 | 1,2,4-Trichlorobenzene | 31.36 |

| 78 | Hexachlorobutadiene | 31.39 |

| 79 | Naphthalene | 31.6 |

Table 1 – RT for TO-15A and EtO.

| GC | Agilent 7890B |

| Injection type | On-column |

| Column | 624Sil MS 60m x 0.25mm x 1.4um |

| Carrier gas | He , constant flow |

| Flow rate | 2mL/min |

| Oven temp | 0°C (hold 5 min) to 60°C at 3.5°C/min (hold 0 min) to 260°C at 24°C/min (hold 5 min) |

| Detector | MS (Agilent 5977A) |

| Acquisition mode | SIM/Scan |

| Scan parameters | |

| Scan range (amu) | 29-226 |

| Scan rate (scans/sec) | 3.7 |

| SIM parameters | |

| SIM ions | 15, 29, 43, 44, 56 |

| Dwell time | 50 |

| Transfer line | 250°C |

| Analyzer type | Quadruple |

| Source type | Extractor |

| Source temp | 230°C |

| Quad temp | 150°C |

| Electron energy | 70eV |

| Solvent delay time | 0 min |

| Tune type | BFB |

| Ionization mode | EI |

| Preconcentrator | Markes Unity 1+ CIA |

| Trap 1 settings | |

| Cooling temp | 5°C |

| Desorb temp | 300°C |

| Desorb flow | 6 mL/min |

| Desorb time | 180 sec |

| Internal Standard | |

| Purge flow | 50 mL/min |

| Purge time | 60 sec |

| Volume | 50mL |

| ISTD flow | 50mL/min |

| Sample | |

| Volume | 400mL |

| Purge flow | 50mL/min |

| Purge time | 60 sec |

| Sample flow | 100mL/min |

Table 2 – GC/MS and preconcentrator settings

While many labs may be reluctant to use cryogenic cooling due to costs and safety issues, it can be a powerful tool to separate out very volatile compounds. Here it was critical in the separation of EtO from methanol and acetaldehyde. In addition, the ability to acquire both SIM and scan MS data allowed for the increased signal to noise ratio for EtO in SIM mode, while maintaining the simplicity full scan for the TO-15A compounds. Together, cyro cooling and SIM/Scan can allow for the relatively simple addition of EtO down to 50ppt to TO-15A analysis.