In this blog, we’ll dive into the often-underestimated world of tubing and fittings in High-Performance Liquid Chromatography (HPLC) and Ultra-High-Performance Liquid Chromatography (UHPLC) systems. We’ll explore how these seemingly insignificant components can make or break your chromatography game. From the impact of excess tubing to selecting the right fittings, we’ll provide you with practical insights and recommendations to optimize your system’s performance.

So, you’ve got a shiny new HPLC column and a top-notch instrument, but your chromatography results are disappointing. What gives? Well, the culprit might just be your tubing and fittings. This blog may shed light on their importance and show you why they deserve your attention.

1. Excess Tubing and Chromatographic Woes:

Believe it or not, excess tubing can wreak havoc on your chromatography. We’ve got an eye-opening article titled “How Extra Column Volume Affects Cannabinoids Analysis and LC Column Choice” that reveals the nitty-gritty details. It’s an essential read to understand how excess volume can mess with your results.

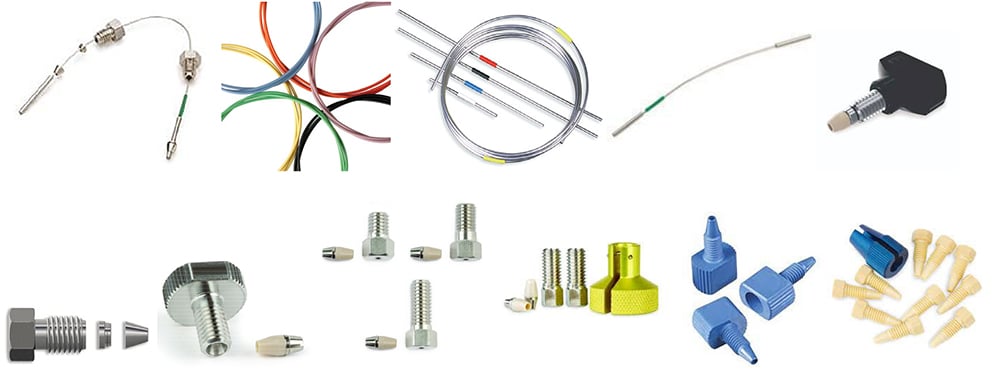

2. Fitting Selection:

Let’s get down to it—choosing the right tubing and fittings is key to a smooth-running HPLC/UHPLC system. Check out this table featuring various fittings, their Restek catalog numbers, pressure limits, and what tubing to use with them:

| Fittings | Restek Catalog # | Pressure limit | Use with what Tubing |

| Standard 1/16″ nuts and ferrules | 26537 | 20,000 psi | stainless steel |

| EXP Reusable Hand-Tight nut w/ferrule | 25937 | 8700+ psi by hand, 20,000+ psi by a wrench | PEEK and stainless steel |

| EXP Hex-Head (two sizes) | 25926, 25930 | 8700+ psi by hand, 20,000+ psi by a wrench | PEEK and stainless steel |

| EXP2 Reusable fittings | 25783 | 20,000 psi+ (1400 bar) tested to 30,000 psi (2068 bar) | PEEK and stainless steel |

| EXP2 TI-LOK All-in-One | 25745 | 18,000 psi (1250 bar) no wrench | PEEK, PEEKsil, Hastelloy C, stainless steel, fused silica |

| PPS Hex-Head | 27714 | 5000 psi (350 bar) | PEEK and stainless steel |

| PEEK-HT | 27713 | 10,000 psi (689 bar) no wrench | PEEK and stainless steel |

| PEEK Hex-Head | 27712 | 5000 psi (350 bar) | PEEK and stainless steel |

| Universal 10-32 PEEK finger tight | 25015, 25016, 27710 | 5000 psi (350 bar) | PEEK and stainless steel |

| Stainless Steel fittings for UHPLC Valco and Rheodyne ferrules | 27727–27735 | 20,000 psi (1375 bar) Valco-Style nuts, 7250 psi (500 bar) Rheodyne-Style nuts | Specific for valves. |

3. Tubing Talk:

Now, let’s talk tubing. Here’s a table that spills the beans on different tubing options, their Restek catalog numbers, pressure limits, and where they shine:

| Tubing | Restek Catalog number | Pressure limit | Instrument |

| Capillary Stainless-Steel Tubing | 25740, 26525–26537 | 600 bar | Agilent instruments |

| PEEK | 27746–27756 | 5000 psi or 7000 psi (varies with internal diameter) | HPLC instruments |

| Stainless-Steel Precut | 25813–25828 | 20,230 psi to 27,850 psi (varies with internal diameter) | UHPLC or HPLC instruments |

| Stainless Steel Coil | 27757–27780 | 10,645 psi to 27,580 psi (varies with internal diameter) | UHPLC or HPLC instruments |

| Flexible Premium Stainless Steel | 27781–27796 27798–27806, 27808 27810–27813 | 20,230 psi to 27,580psi (1395 bar to 1902 bar) (varies with internal diameter) | UHPLC or HPLC instruments |

| Secure-Fit (PEEK and Stainless Steel) | 25211, 26513, 25188, 25236, 25237 | 400 bar | HPLC instruments |

4. Tips and Tricks for Tubing and Fittings:

We’ve got your back with some handy tips and tricks to get the most out of your tubing and fittings:

- Keep It Lean: Minimize extra tubing volume to avoid pesky gradient delays. Long and narrow tubing can crank up the pressure, so keep it in check. Minimizing LC System Volume

- The Right Fit (ID): Match the tubing’s internal diameter (ID) with your system’s requirements. Using the wrong ID can result in wider but shorter peaks. For HPLC systems with 4.6 mm ID columns, go for tubing with an ID of 0.17 mm. UHPLC systems call for 0.12 mm ID or 0.07 mm ID. Semi-prep and prep HPLC systems use 0.020-inch tubing or bigger.

- Peek at PEEK: PEEK tubing is great when you need a bioinert system, have compounds that don’t play well with stainless steel, or if you frequently change connections between the autosampler and column. Just watch out for solvents like tetrahydrofuran, DMSO, or chlorinated solvents—they can make PEEK tubing brittle.

- Don’t Get Swaged Away: Steer clear of pre-swaged or nonadjustable fittings when connecting to HPLC columns. They won’t give you the flexibility you need.

- Cut It Right: Use a clean-cut tubing cutter (catalog 25069) for PEEK tubing.

- Seat It Right: Properly seat those fittings to avoid peak shape problems. Leaving gaps inside the fittings can lead to poor peaks, lower resolution, and even carryover issues.

Tubing and fittings might be small, but they pack a punch in HPLC/UHPLC systems. Don’t underestimate their impact on your chromatography. By following our tips and giving them the attention, they deserve, you’ll unlock the full potential of your liquid chromatography adventures.