- Linearity for all reference compounds exceeds method requirements.

- SilTite µ-Union connector provides leak-free connection; retention gap improves analyte focusing and extends column life.

- Stable Rtx-Biodiesel TG columns minimize bleed at high temperatures for more accurate results.

Biodiesel oil is biodegradable, nontoxic, and contains no aromatic compounds. Compared to petroleum diesel, biodiesel combustion produces less air pollutants, such as carbon monoxide, sulfur dioxide, hydrocarbons, particulates, and other air toxic compounds. The “B” number in B100, B20, or B10 material designates the percentage of biodiesel in a biodiesel/petroleum diesel blend (e.g., B20 is 20% biodiesel and 80% petroleum diesel).

Transesterification of the vegetable oil, animal fat, or used oils from which biodiesel oil is prepared yields two main products: fatty acids methyl esters (biodiesel oil) and glycerin. Glycerin is removed from biodiesel oil because excessive amounts of residual free glycerin, unreacted starting material, or reaction intermediates (e.g., mono-, di-, and triglycerides) can foul injectors and form deposits on valves, pistons, and injector nozzles. Separation of the glycerin during storage or in vehicle fuel tanks can reduce the shelf life of the product.

The American Society for Testing and Materials (ASTM) describes several physical and chemical testing methods for biodiesel oil. In this article, we focus on gas chromatographic method ASTM D6584-17, which sets the industry standards for testing B100 biodiesel oil. Through this method, analysts can quantify free glycerin in the range of 0.0005 to 0.0195 mass percent and total glycerin from 0.0090 to 0.4276 mass percent. The column recommended for the analysis is a 10 or 15 m long 0.32 mm ID fused silica column with a 0.1 µm film of 5% diphenyl/95% dimethyl polysiloxane. The stationary phase and the polyimide coating on the tubing must be sufficiently robust to withstand high temperatures, and the column must exhibit low bleed.

In this work, the Rtx-Biodiesel TG fused silica column was evaluated for conformance to ASTM D6584-17 method requirements. In addition, we tested the use of a 2 m x 0.53 mm ID deactivated fused silica retention gap, coupled to the analytical column with a SilTite µ-Union connector, to improve analyte focusing. Analysis was performed using a GC equipped with a cool on-column injector and an FID. Hydrogen, supplied from a Parker hydrogen generator, was both the FID fuel gas and, for optimum performance, the carrier gas. Calibration standards were prepared and derivatized per ASTM D-6584-17, and the GC parameters were set as recommended in the method.

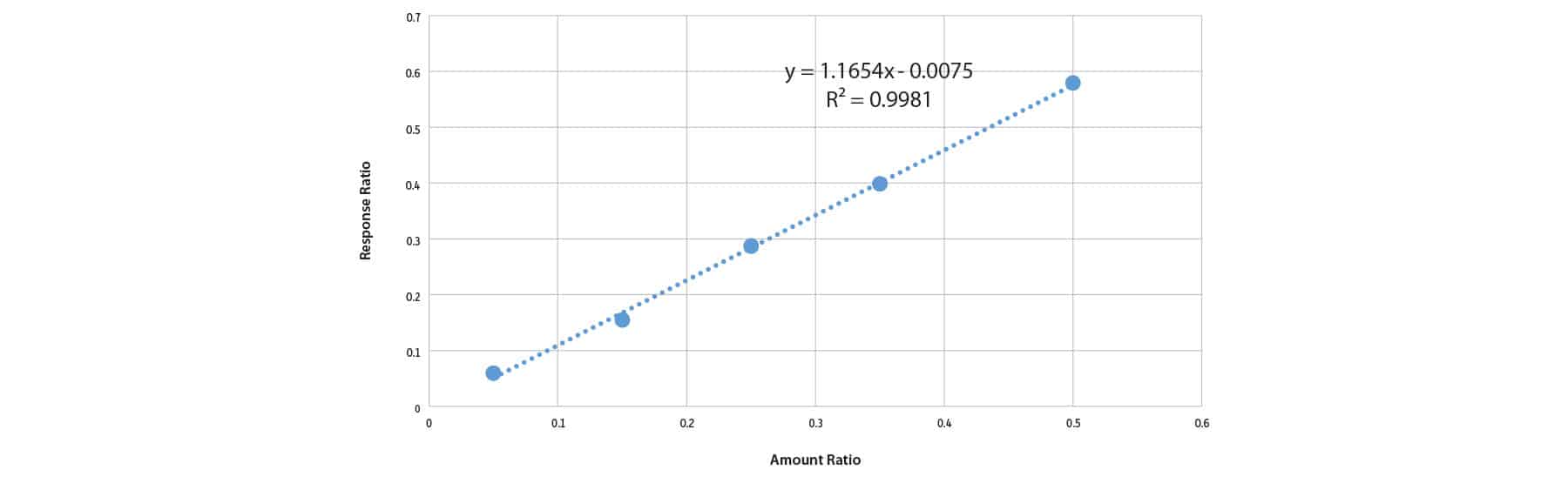

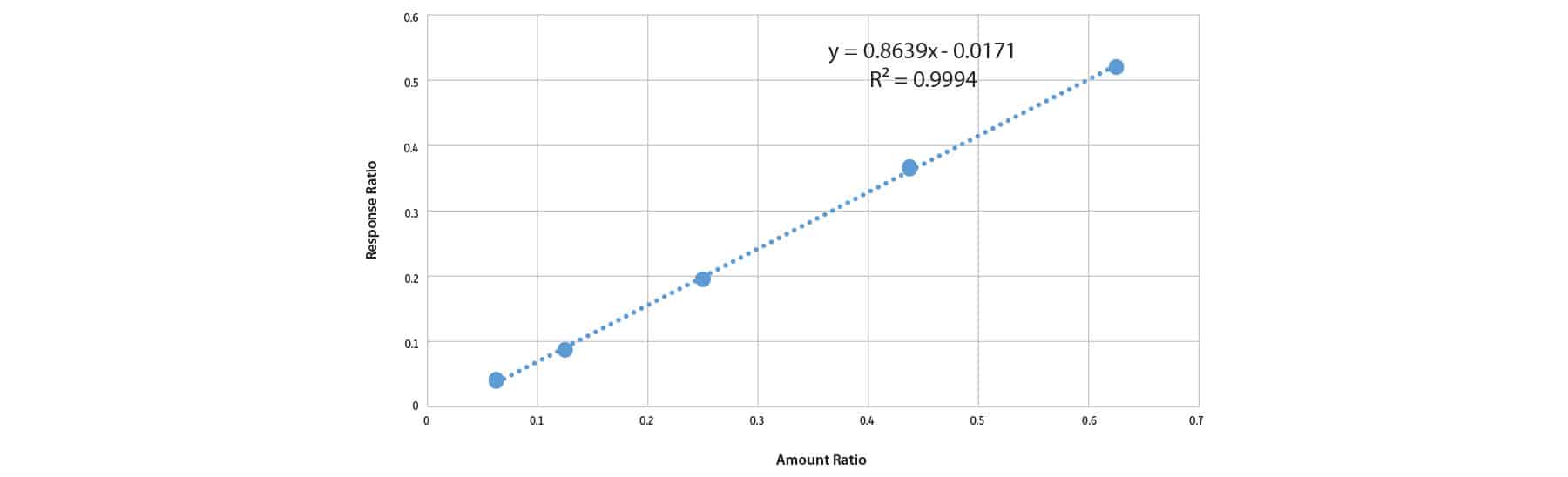

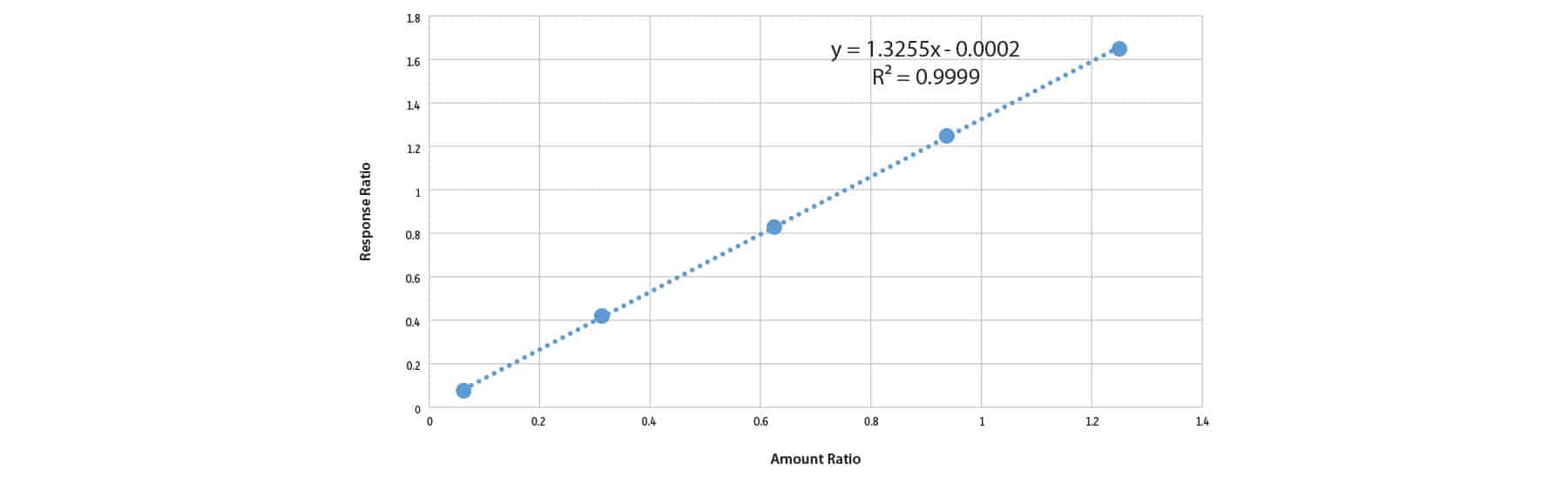

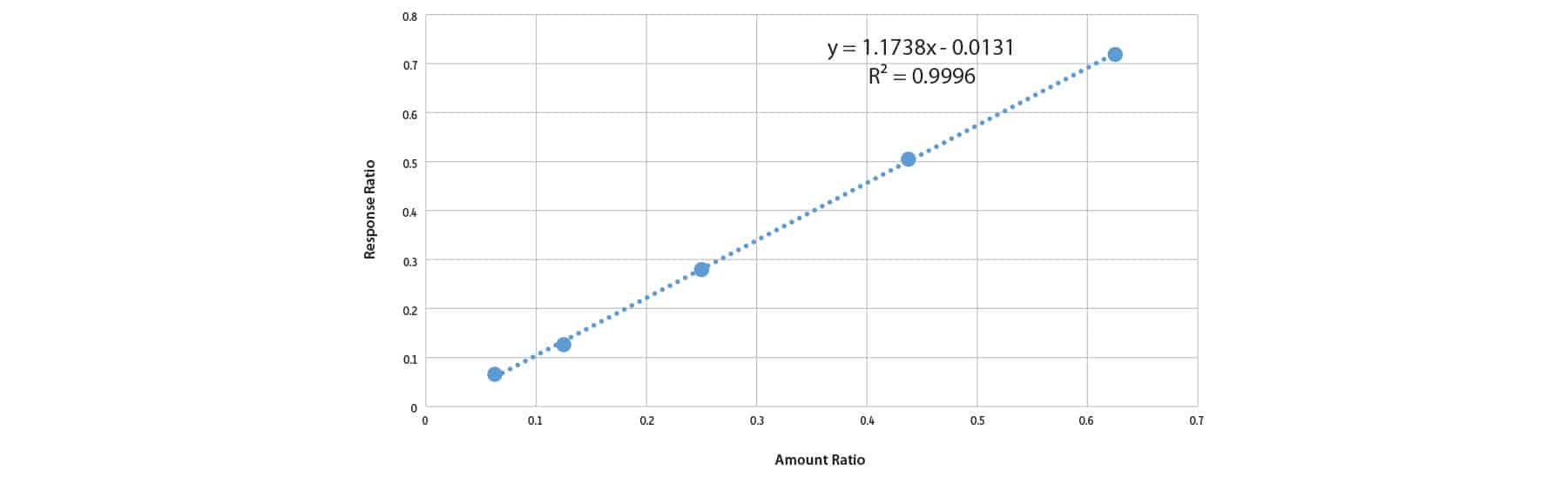

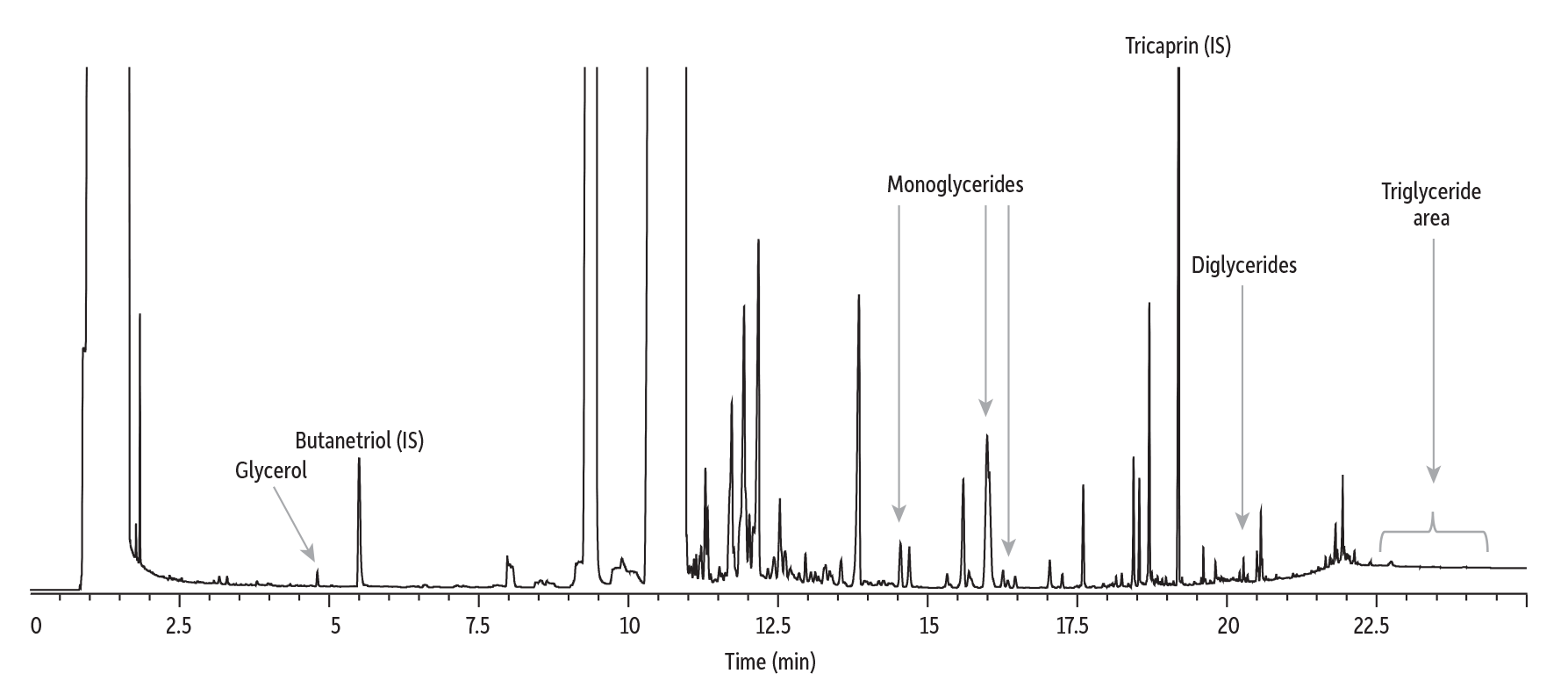

As shown in Figure 1, the calibration curves for each reference compound, including triolein, comply with the established method linearity criteria (r2 = 0.99). After developing the calibration curves, we fortified a sample of canola B100 biodiesel oil with the two internal standards, butanetriol and tricaprin, and then silylated the mixture with MSTFA. The chromatographic analysis of glycerin and glycerides in biodiesel are presented in Figure 2. The monoglycerides were identified using a custom standard containing monopalmitin, monoolein, and monostearin; whereas, the diglyceride and triglyceride zones were determined using relative retention factors as described in the ASTM D6584-17. Mass percent results using the Rtx-Biodiesel TG column were 0.007% free glycerin, 0.203% bound glycerin, and 0.210% total glycerin, which are all within the target range of the method. Column performance at high temperatures was also strong as evidenced by the low bleed that was observed even at 380 °C.

The addition of the retention gap helped focus analytes at the head of the column so sharp, narrow peaks were obtained; however, there is another benefit to using it. The retention gap also serves as a guard column, trapping the heavy molecular weight matrix components commonly found in biodiesel. Repeated analysis of biodiesel oil will eventually decrease column performance and cause peak tailing for some analytes. When this occurs, the lifetime of the analytical column can be extended by replacing the retention gap/guard column, and SilTite µ-Unions fittings make it simple to obtain a reliable, leak-free connection.

In conclusion, using an Rtx-Biodiesel TG column, coupled to a retention gap through a SilTite µ-Union connector, provided the performance required to meet the stringent standards of ASTM D6584-17 for the analysis of glycerin and glycerides in biodiesel. In this application, the retention gap also serves as a guard column, protecting the analytical column from matrix contaminants.

Glycerin (5-50 mg)

Monoolein (50-1000 mg)

Diolein (50-500 mg)

Triolein (50-500 mg)

GC_PC1367

Peaks

| Peaks | tR (min) | |

|---|---|---|

| 1. | Glycerol | 4.80 |

| 2. | 1,2,4-Butanetriol (IS) | 5.50 |

| 3. | Monoglycerides | as shown |

| 4. | Tricaprin (IS) | 19.19 |

| 5. | Diglycerides | 20.16 – 20.9 |

| 6. | Triglycerides | 22.27 – 25.15 |

Conditions

| Column | Rtx-Biodiesel TG with 2 m x 0.53 mm ID retention gap, 15 m, 0.32 mm ID, 0.1 µm (cat.# 10293) |

|---|---|

| Standard/Sample | |

| Soy B100 biodiesel | |

| Tricaprin (1,2,3-tricaprinoylglycerol) (cat.# 33025) | |

| (s)-(-)-1,2,4-Butanetriol (cat.# 33024) | |

| Diluent: | Heptane |

| Injection | |

| Inj. Vol.: | 1 µL cool on-column |

| Temp. Program: | Track oven |

| Oven | |

| Oven Temp.: | 50 °C (hold 1 min) to 180 °C at 15 °C/min to 230 °C at 7 °C/min to 380 °C at 30 °C/min (hold 2 min) |

| Carrier Gas | H2, constant flow |

| Flow Rate: | 2.7 mL/min |

| Detector | FID @ 380 °C |

|---|---|

| Instrument | Agilent 7890B GC |

| Sample Preparation | Sample preparation followed ASTM D6584-17: Soy biodiesel B100 was fortified with internal standards (butanetriol and tricaprin) and derivatized using MSTFA. |